WAAM Ti-6242 microstructure refinement

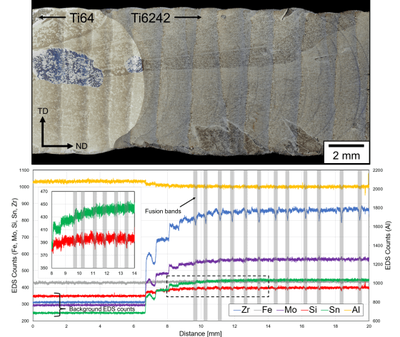

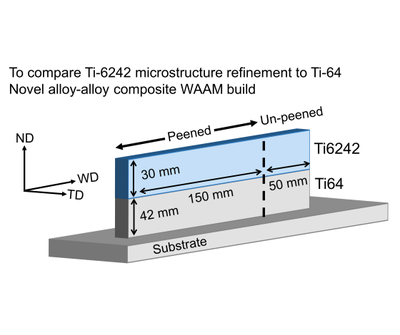

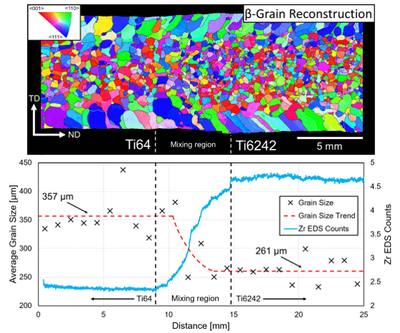

The titanium alloy Ti–6Al–2Sn–4Zr–2Mo–0.1Si (Ti6242) has been deposited for the first time by a directed energy deposition process using a wire and arc system—i.e., wire-arc additive manufacturing (WAAM)—with and without inter-pass machine hammer peening, and its microstructure investigated and compared to the more commonly used alloy Ti–6Al–4V (Ti64). The application of inter-pass machine hammer peening—where each added layer was deformed before deposition—successfully refined the strongly textured, coarse, columnar b-grain structure that is commonly seen in a + b titanium alloys, producing a finer equiaxed grain structure with a near-random a texture. The average grain diameter and texture strength decreased with the peening pitch. When Ti6242 was deposited under identical conditions to Ti64, by switching the alloy feed wire in-situ, the refined b-grain size decreased across the alloy-to-alloy transition reaching on average 25 pct less in Ti6242 than in Ti64. A similar 25 pct scale reduction was also found in the Ti6242 a-lath transformation microstructure. This comparatively greater microstructure refinement in Ti6242 was attributed to the dissimilar alloying elements present in the two materials; specifically, molybdenum, which has a lower diffusivity than vanadium and led to slower b-grain growth during reheating as well as a finer transformation microstructure.

E. Davis, A. E. Caballero, R. Biswal, S. Williams, and P. B. Prangnell, “Comparison of Microstructure Refinement in Wire-Arc Additively Manufactured Ti–6Al–2Sn–4Zr–2Mo–0.1Si and Ti–6Al–4V Built With Inter-Pass Deformation,” Metallurgical and Materials Transactions A, vol. 53, no. 11, pp. 3833–3852, Nov. 2022, doi: 10.1007/s11661-022-06811-1.

Information

- Research Area:Material Development

-

Investigators:

Armando Caballero

, Phil Prangnell, Alec Davis, Romali Biswal, Stewart Williams - Publications:https://doi.org/10.1007/s11661-022-06811-1