Process Modelling

Developing physics based process models for process design and understanding.

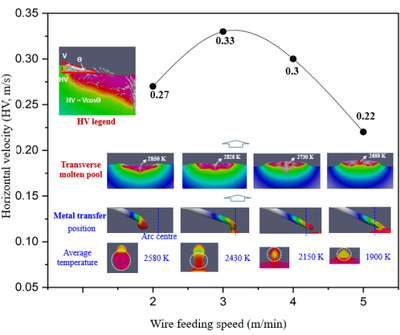

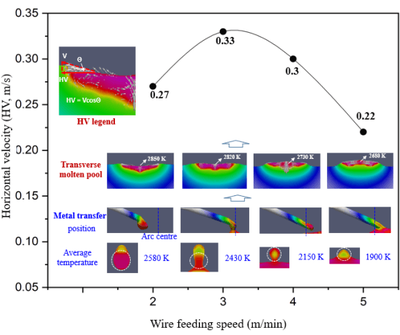

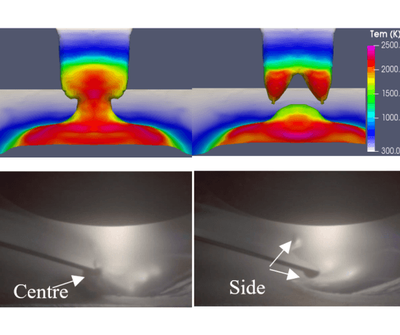

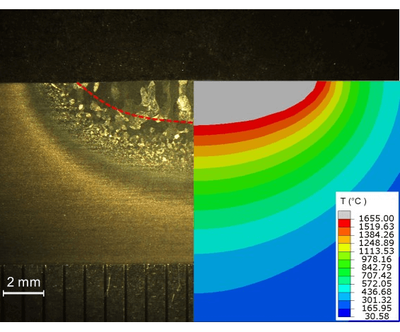

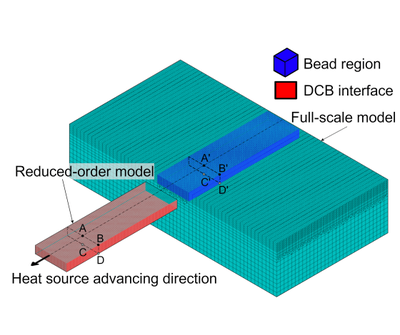

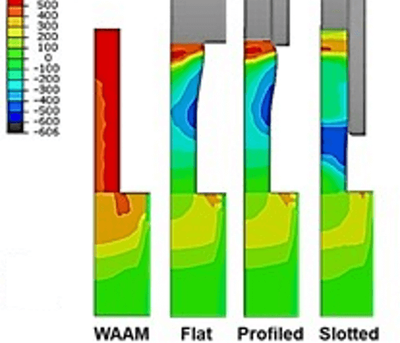

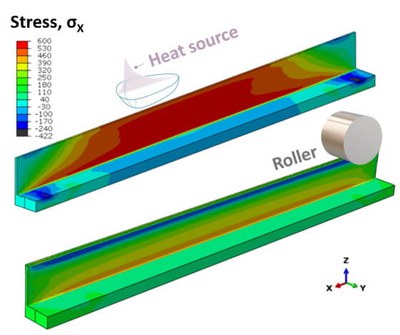

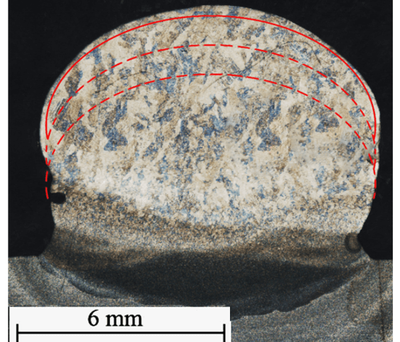

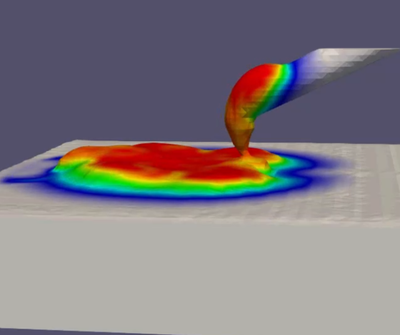

The target of this research area is to assist the MES DED process development though the fundamental understanding with physical insights into process behaviour and accurate predictions of interactions between thermal fields, melt pool development and bead formation. A fluid flow model has been developed on the simulation of the coupled mass and thermal flow in the melt pool, and their effect on the material solidification and bead formation. The model has been validated on the plasma and wire AM process. Good agreements between the simulation and the experimental results have been achieved. This model will be extended for the multi-energy source with improved computational efficiency. Three FE models have been developed, which are on wire melting, hybrid laser and arc process, as well as scanning laser. The model on the wire melting has shown a melting efficiency of two times can be achieved by using a strip wire comparing to a round wire. Further development will focus on matching the laser beam profile to the wire shape to achieve the highest melting efficiency. Both transient and steady state FE models have been developed for predicting the thermal distribution of the hybrid laser and arc process. This model will be used for studying the thermal interactions of the different configurations of the arc and the lasers. A transient FE model has been developed for the scanning laser. Further work will be focus on the characterisation of the scanning laser and the development of an equivalent stead state heat source.

Research area leader

Research topics & Activities

List of all work packages related to the research area with current activities