Non-Destructive Evaluation of WAAM Components - Imaging and Defect Detection

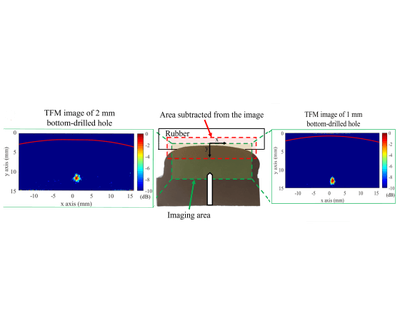

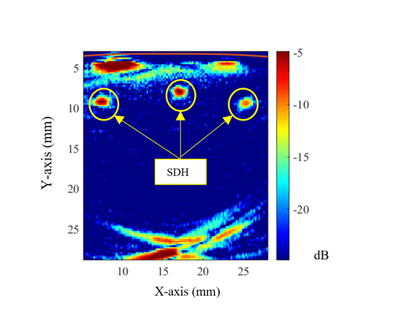

The roller probe, containing an UT array, allows to inspect WAAM components through a delay line in form of liquid or solid infill and an outer rotating rubber tire. The UT data are collected in Full Matric Capture (FMC) mode acquiring signals in time domain for every possible transmitter-receiver combination of the array elements. The data can then be processed in almost real-time to form high resolution Total focusing method (TFM) images leveraging the delay and sum algorithms. The image provides a high sensitivity to smaller defects. However, in case of inspection through multiple media, the refractions at interfaces caused by the acoustic mismatch should be considered in calculations creating additional challenges. The research aims to use UT FMC data to analyse the curvature of the WAAM surface inspected by the roller probe and to develop an Adaptive TFM (ATFM) algorithm to take the detected curvature into account while forming the images.

Information

- Research Area:Non-Destructive Testing

- Publication date:06 July 2020

Activities

List of all current activities related to the work package