Material Modelling

Developing microstructure models to design bespoke materials and predict the process–property relationships

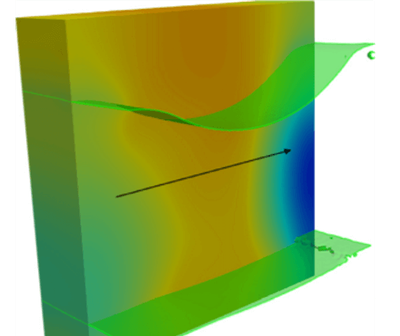

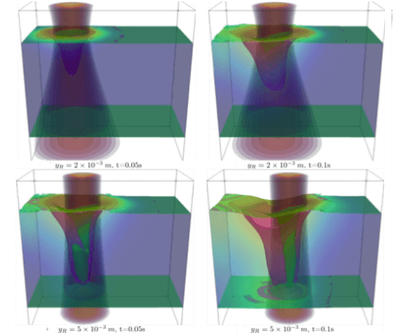

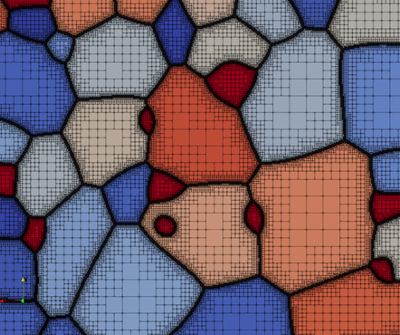

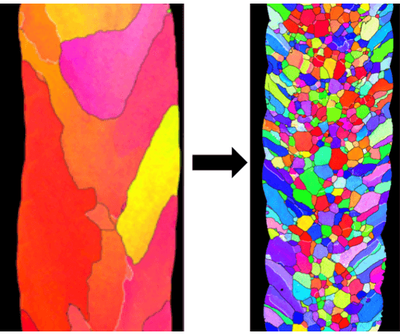

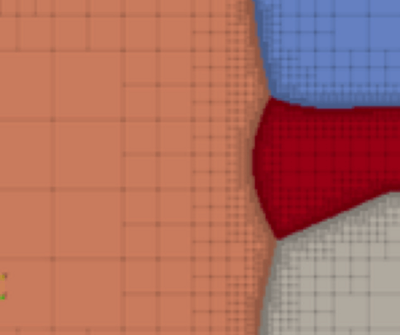

Mechanical performance of WAAM components is largely determined by their microstructure, which in turn is greatly influenced by solidification conditions and heat treatment. Experimentally probing the various parameters of solidification and heat treatment for different alloys is time consuming and expensive. The microstructure models give an insight into grain growth, dendrite evolution and segregation and this will assist optimising the processing parameters. With the CALPHAD (Calculation of Phase Diagram) integrated models, the behaviour of a variety of multicomponent systems can be replicated and this will help develop urgently needed WAAM specific alloys.

The ability to predict elimination of microsegregation is particularly important in WAAM, because the repeated heat source passes may provide in-situ homogenisation. Predicting whether this has adequately homogenised the WAAM build, and what additional treatment may be required, is vital to creating a cost effective WAAM process that reduces any unnecessary post-WAAM heat treatments. A CALPAD based finite difference diffusion model is used for these homogenisation predictions.

Research area leader

Research topics & Activities

List of all work packages related to the research area with current activities

This work package currently has no activities yet.

This work package currently has no activities yet.

This work package currently has no activities yet.