Ti grain refinement

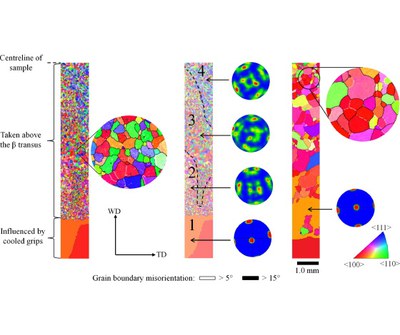

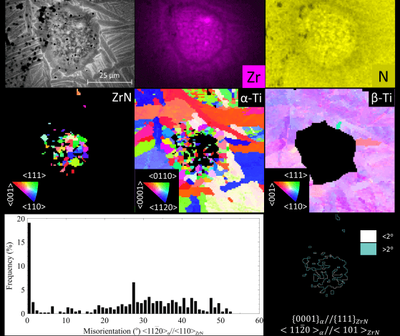

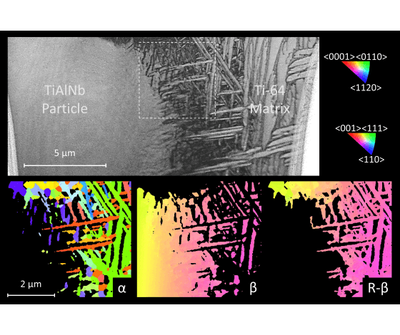

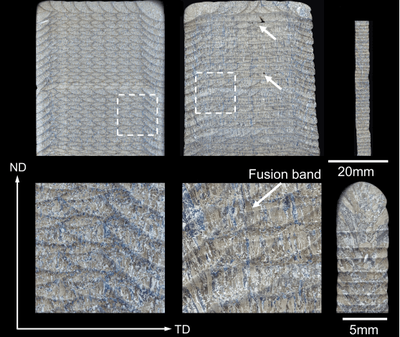

Titanium is an attractive material for additive manufacturing as its conventional processing is expensive, time consuming and requires significant machining resulting in high buy to fly ratios, however, AM Ti parts have solidification structures primarily consisting of large columnar grains oriented in the build direction, resulting in large anisotropy and poor mechanical properties. These form during solidification due to a narrow solidification range and low constitutional undercoolings, especially in common alloys such as Ti-64, which results in solidification by epitaxial growth from the substrate and previous layers rather than nucleation of new solid. In order to reduce anisotropy and improve mechanical properties, alloy and process modification methods are being investigated to modify and refine the primary beta grain

Information

- Research Area:Material Development

- Duration:60 months

- Publication date:27 March 2020

Activities

List of all current activities related to the work package