Observation of annealing twins

On the observation of annealing twins during simulating β-grain refinement in Ti–6Al–4V high deposition rate AM with in-process deformation

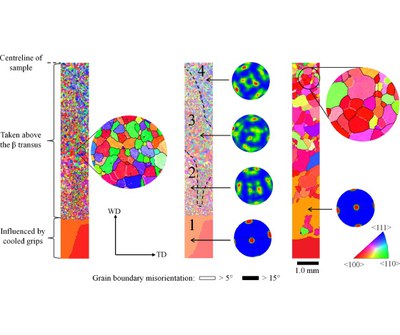

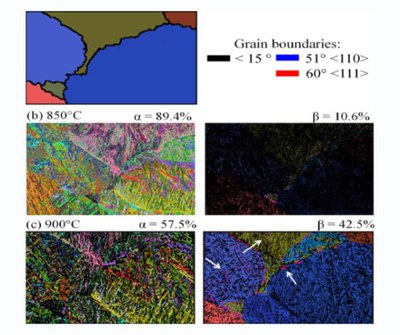

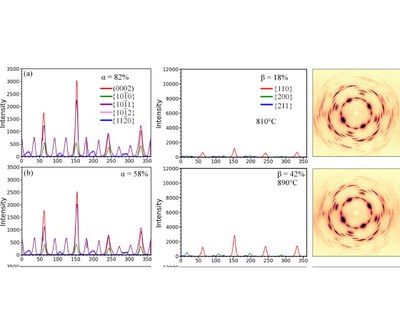

Additive Manufacture (AM) of Ti–6Al–4V frequently leads to undesirable, coarse, columnar β-grain structures with a strong <100> fibre texture. In Wire-Arc AM (WAAM), it has been found that the application of a low plastic strain, by methods such as inter-pass rolling, can disrupt β columnar growth and produce a refined, equiaxed grain structure that is more randomly orientated. The origin of this desirable effect has been investigated by thermo-mechanical simulation, direct in-situ EBSD observation, as well as by real-time synchrotron X-ray diffraction (SXRD) during rapid heating. These complementary approaches have shown that, when starting with a WAAM microstructure, the grain refinement process produces a unique micro-texture represented by a four-pole motif symmetrically centred on the parent grain {100} orientations. These new β-grain orientations can be reproduced by a double {112}<111> twinning operation, which produces 12 new, unique, β-orientation variants. High-resolution orientation-mapping techniques and in-situ SXRD heating simulations suggest that the prior β does not twin during deformation, but rather the grain refinement and related texture may be caused by annealing twinning during β re-growth on rapid re-heating of the deformed AM microstructure. Although this is the first time such a unique texture has been observed in a deformed and β annealed Ti–6Al–4V material, it was only found to dominate under the unusual conditions that occur in AM of rapid heating – a fine, lightly deformed α transformation microstructure, with a very coarse starting β-grain structure.

J. Donoghue et al., “On the observation of annealing twins during simulating β-grain refinement in Ti–6Al–4V high deposition rate AM with in-process deformation,” Acta Mater., 2020, doi: 10.1016/j.actamat.2020.01.009.

Information

- Research Area:Material Development

- Publication date:01 March 2020

-

Investigators:

Phil Prangnell

, Alec Davis - Publications:https://doi.org/10.1016/j.actamat.2020.01.009