Material Performance

Crucial data on formation of defects and their effect on mechanical performance will be determined.

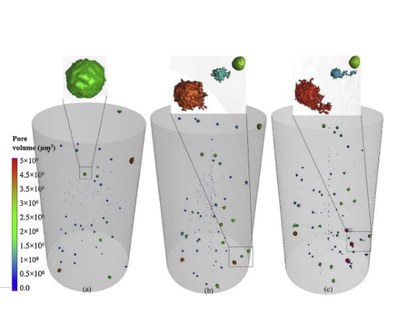

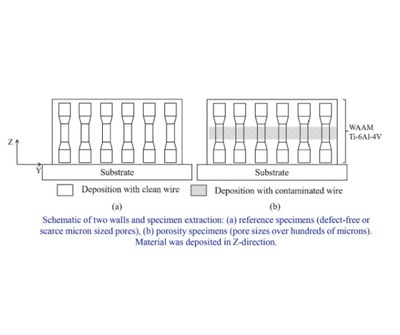

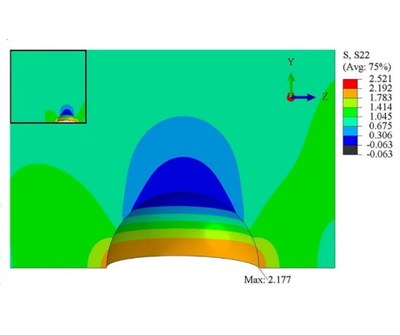

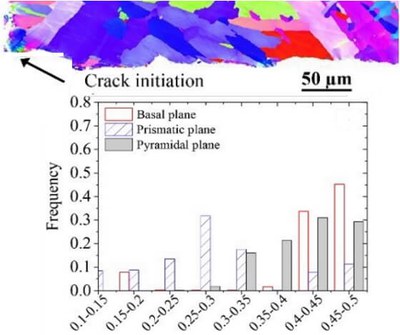

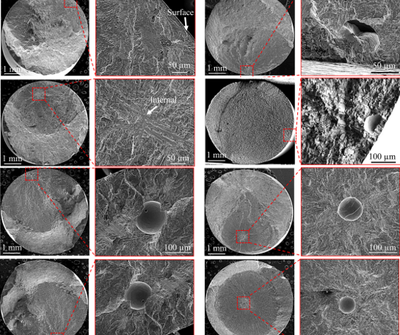

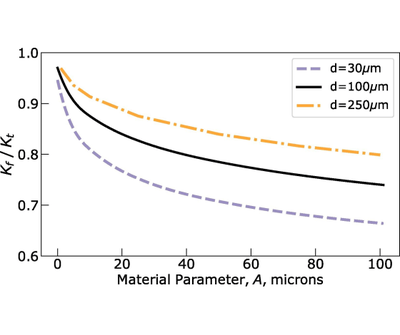

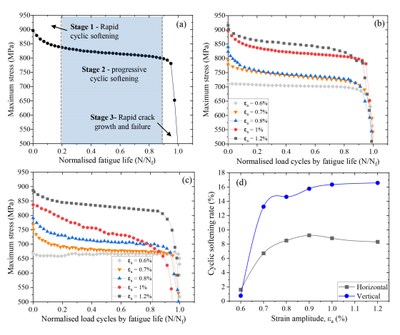

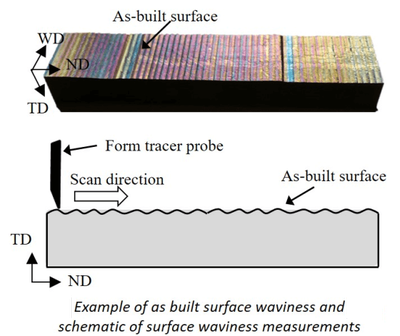

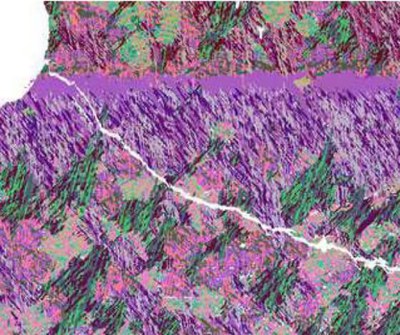

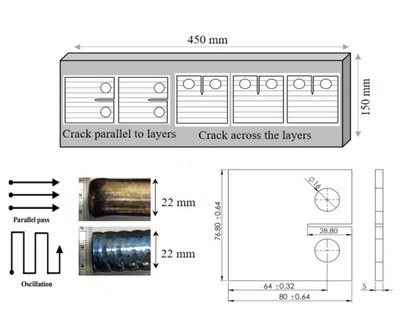

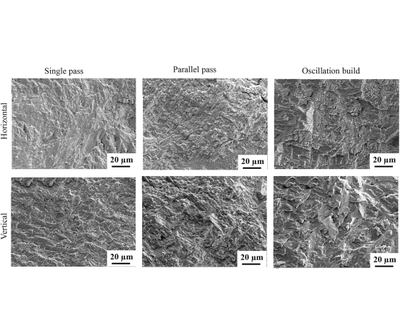

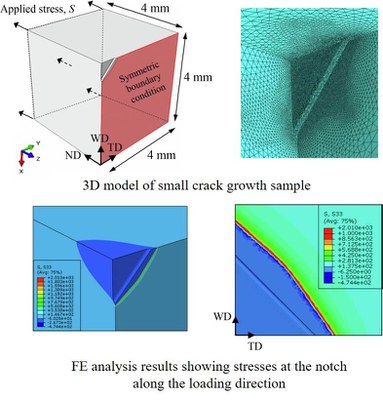

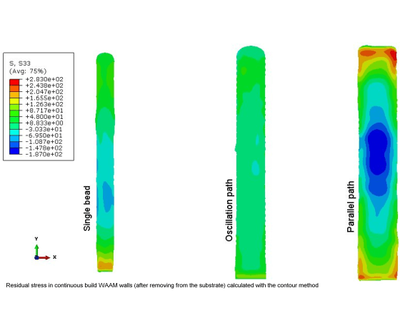

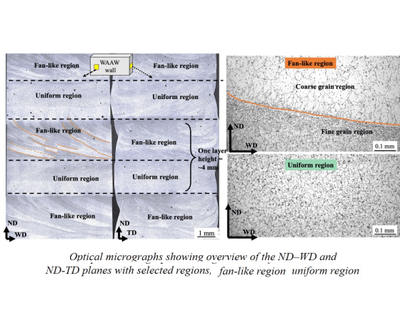

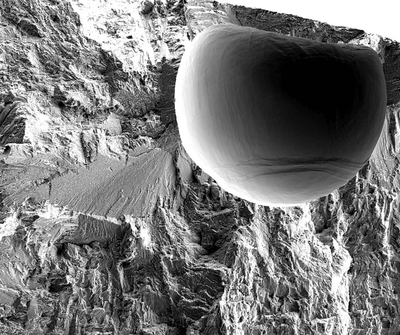

Investigation of titanium alloy Ti-6Al-4V is conducted under three different topics: (i) high cycle fatigue and the effects of porosity defect and as-built surface texture; (ii) residual stresses in WAAM builds and in test specimens extracted from large build; (iii) fatigue crack growth rate and the effects of process induced residual stress and heterogeneous microstructure. The main objectives are to find the material fatigue and fracture properties under the influence of microstructure and defects, to develop models and methods for assessment of defect tolerance and defect criticality under fatigue loads, and to ultimately assess the durability and damage tolerance performance for qualification of wire additive manufactured titanium alloy used in safety critical structures. Research methods include computational modelling by fracture mechanics approach, experimental testing, and material characterisation at micro and meso scales using advanced imaging facilities, e.g. X-ray computed tomography, fractography with scanning electron microscope, micro texture analysis via Electron Back Scattered Diffraction (EBSD). Residual stresses are evaluated by the contour method.

Research area leader

Research topics & Activities

List of all work packages related to the research area with current activities