Fatigue crack growth behaviour of WAAM built Al-Mg-Sc alloy

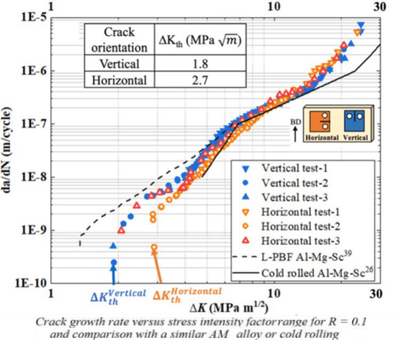

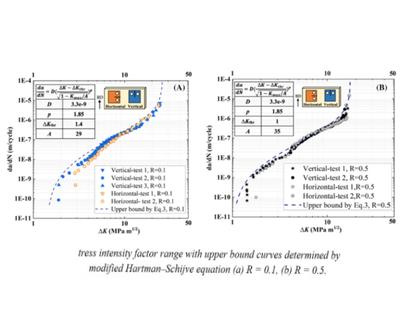

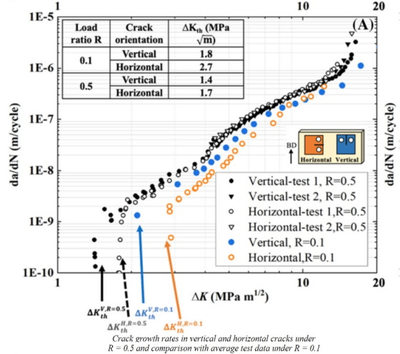

Additive manufacturing (AM) of Al–Mg–Sc alloys has received considerable interest from the aerospace industry owing to their high specific strength and suitability for AM processes. This study has investigated the fatigue crack growth behavior in an Al–Mg–0.3Sc alloy made by wire and arc additive manufacturing (WAAM) process. The material was deposited using Cold Metal Transfer-Advanced (CMT-Adv) process and a single bead deposition strategy. A detailed microstructure analysis along the build direction mainly shows two distinct regions, namely, the fan-like region and the uniform region. Furthermore, fan-like region consisting alternative layers of coarse and fine grain microstructure bands which is the result of pulsated deposition during CMT process. Fatigue crack growth tests were conducted with two different crack orientations at cyclic load ratios of 0.1 and 0.5. At the lower load ratio, the horizontal crack showed a faster growth rate owing to the smaller grains and coarser second phase particles that the crack tip had encountered when it propagated along the material build direction. The anisotropy in crack growth rate was mainly caused by the grain size effect. When the applied stress intensity factor range exceeded the value of 10 MPa m1/2, an isotropic crack growth rate between the two crack orientations was measured. This is due to the microstructural influence being overcome by the governing parameter of fracture mechanics. At the higher load ratio of 0.5, crack growth rate is isotropic, and the threshold stress intensity factor range was much lower than that tested under load ratio 0.1. Finally, the modified Hartman–Schijve equation has been successfully employed to represent the crack growth rates in all three regions.

J. Ye, A. K. Syed, X. Zhang, E. Eimer, and S. Williams, “Fatigue crack growth behavior in an aluminum alloy Al–Mg–0.3Sc produced by wire based directed energy deposition process,” Fatigue Fract Eng Mater Struct, vol. 46, no. 10, pp. 3927–3938, Oct. 2023, doi: 10.1111/ffe.14113.

Information

- Research Area:Material Performance

-

Investigators:

Jin Ye

, Abdul Khadar Syed, Eloise Eimer, Xiang Zhang, Stewart Williams - Publications:https://doi.org/10.1111/ffe.14113