Non-Destructive Testing

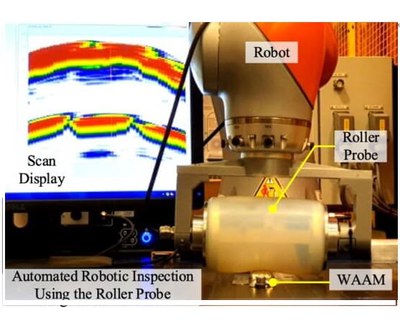

Developing new in-process NDE techniques suitable for DED AM.

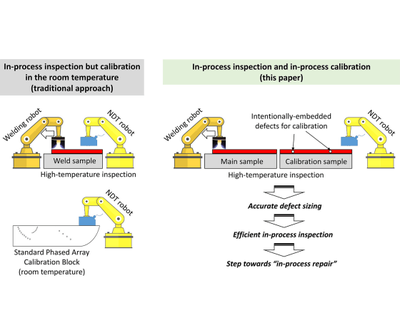

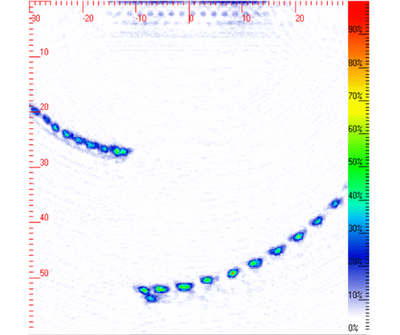

In-process non-destructive testing (NDT) of WAAM components is an important part of the quality assurance of manufactured parts. Traditional NDT is deployed post manufacture often on finished or near finished parts. Deploying NDT earlier in the manufacturing process is advantageous as it allows for identifying problems earlier in the manufacturing process, potentially saving time and money. For metal additive manufacture (AM) an additional benefit of in-process inspection is that by finding defects during build, this opens a pathway for in-process corrective action to be performed (re-melting or machining and re-deposition).

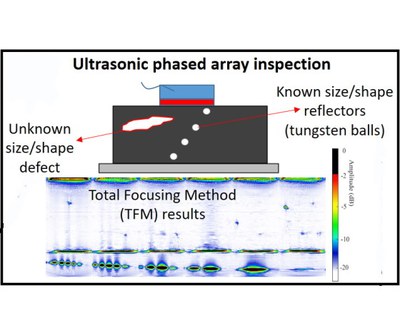

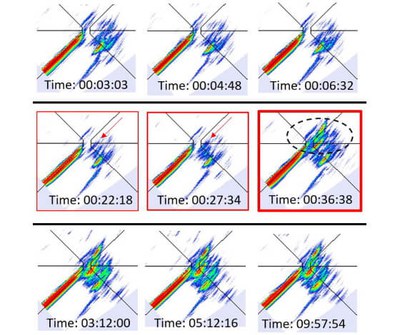

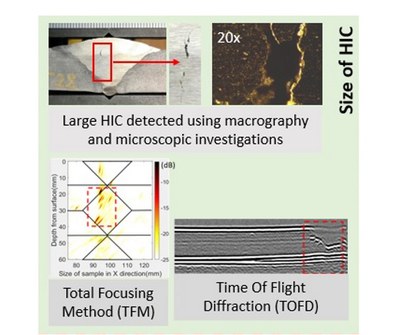

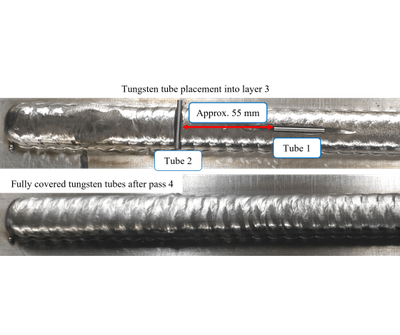

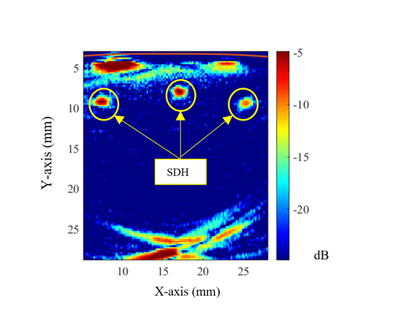

Significant effort is required to move towards fully in-process identification of defects such as inclusions, porosity and lack of fusion.

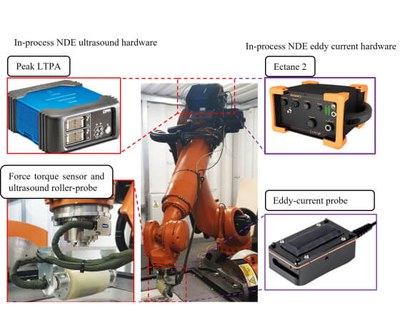

The main challenges to address focus around:

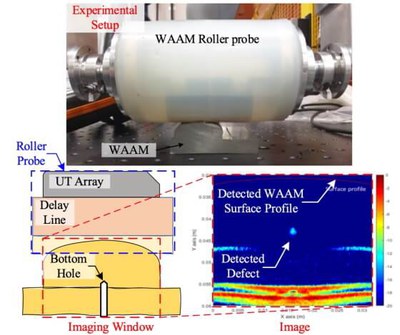

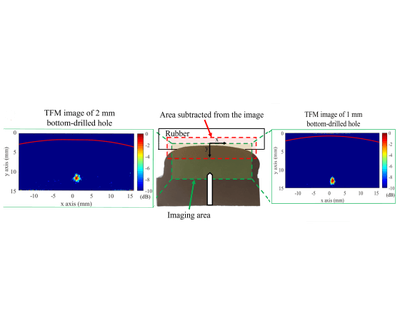

- The transduction process (which process-compatible physical sensing technique is employed)

- The deployment process (how the measurement is deployed in-process)

- The data interpretation process (how data is interpreted and used to correct the process)

Research area leader

Research topics & Activities

List of all work packages related to the research area with current activities