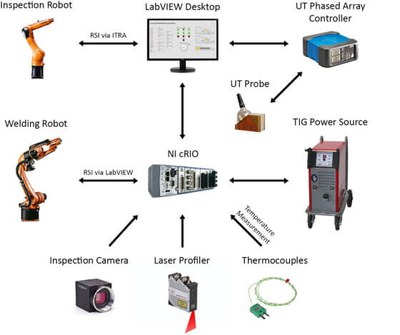

In-process inspection system

Continuous monitoring of an intentionally-manufactured crack using an automated welding and in-process inspection system

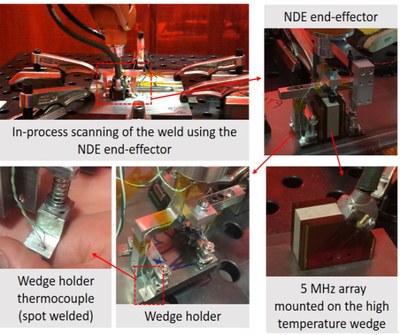

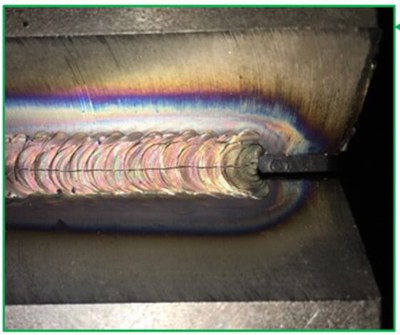

Automated weld deposition coupled with the real-time robotic Non-Destructive Evaluation (NDE) is used in this work. For performance verification of the in-process inspection system, an intentionally embedded defect, a tungsten rod, is introduced into the multi-pass weld. A partially-filled groove (staircase) sample is also manufactured and ultrasonically tested to calibrate the real-time inspection implemented on all seven layers of the weld which are deposited progressively. The tungsten rod is successfully detected in the real-time NDE of the deposited position. The same robotic inspection system was then used to continuously monitor an intentionally-manufactured crack for 20 h. The crack was initiated 22 min after the weld ended and it grew quickly within the next 1.5 h. The crack growth stopped approximately after 2 h and no considerable change in the reflection signal was detected for the next 18 h of monitoring.

Y. Javadi et al., “Continuous monitoring of an intentionally-manufactured crack using an automated welding and in-process inspection system,” Mater. Des., 2020, doi: 10.1016/j.matdes.2020.108655.

Information

- Research Area:Non-Destructive Testing

- Publication date:08 April 2020

-

Investigators:

Gareth Pierce

, Yashar Javadi, Charles Macleod, Anthony Gachagan, Momchil Vasilev - Publications:https://doi.org/10.1016/j.matdes.2020.108655