Process compatible non-destructive testing

Investigating the effect of residual stress on hydrogen cracking in multi-pass robotic welding through process compatible non-destructive testing

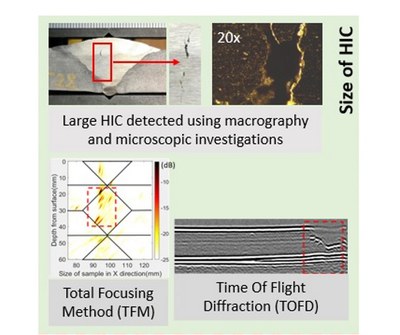

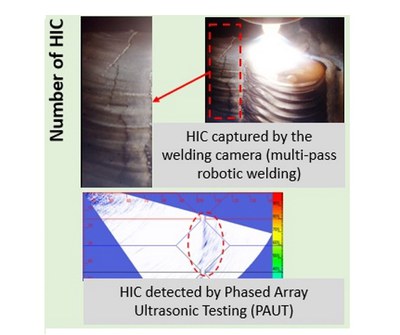

In this work, we used our in-process inspection system to study the negative effect of welding residual stresses on the hydrogen cracking. The crack was monitored in real-time using high-temperature in-process inspection. We manufactured four samples using our 6-axis welding robot and in two separate batches. The difference between the two batches was the clamping system used, which resulted in different amounts of welding residual stress. We then used localised water-quenching method, where water was sprayed over a specific weld pass in a predetermined position, to manufacture the hydrogen cracks in the samples. We believe that it was an innovative approach to repeatably manufacture high and low residual stress samples to control the size and location of the subsequently induced hydrogen cracks. The same Phased-Array Ultrasonic Testing (PAUT) system we are going to use in NEWAM project was implemented during the welding process (a high-temperature in-process method similar to what is required for WAAM samples), to detect the hydrogen cracking in real-time. The residual stresses in both batches were measured using the hole-drilling method, where a difference in transversal residual stress of 78MPa was found between the two samples. Based on the PAUT results and microscopic investigations, the batch with higher residual stress resulted in larger size and number of hydrogen cracks.

Javadi et al., “Continuous monitoring of an intentionally-manufactured crack using an automated welding and in-process inspection system,” Mater. Des., 2020, doi: 10.1016/j.matdes.2020.108655.

Information

- Research Area:Non-Destructive Testing

- Publication date:08 April 2020

-

Investigators:

Ehsan Mohseni

, Yashar Javadi, Charles Macleod, Anthony Gachagan, Nina Sweeney, Momchil Vasilev - Publications:https://doi.org/10.1016/j.jmapro.2020.03.043