High-temperature ultrasound roller probe for high-integrity weld inspection

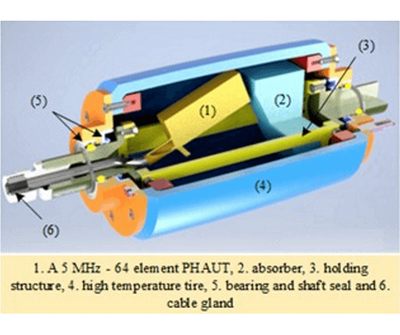

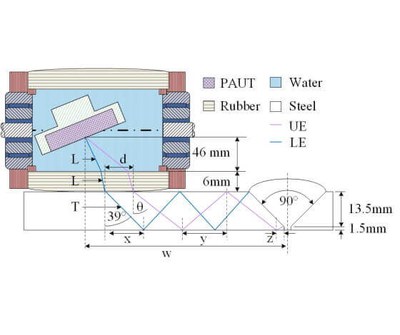

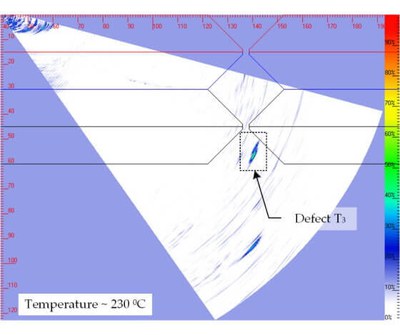

Non-destructive inspection of high-integrity welds is traditionally performed post-process, and the sample is at ambient temperature. This can leads to complex and expensive rework, reduced throughput, and higher lead times. Inspecting either as the weld is deposited or between weld passes makes it possible to identify defects earlier in the process and rectify them. Traditional ultrasonic inspection is severely limited in this application due to the high temperatures associated with the process. Therefore, the authors propose a novel high-temperature ultrasound phased array roller probe to perform in-process inspection of multipass welds. The new roller probe can operate at temperatures up to 350°C and perform angled weld inspection using 55° shear waves. The roller probe's seamless rotation enables continuous inspection and makes it well-suited to integrate within automated environments commonly employed for high-integrity welding applications. The probe demonstrated the capability to detect calibration side-drilled holes at room temperature and artificial defects embedded into a real weld at high temperatures.

R.K. W. Vithanage et al., “A Phased Array Ultrasound Roller Probe for Automated in-Process/Interpass Inspection of Multipass Welds,” IEEE Transactions on Industrial Electronics, vol. 68, no. 12, Dec. 2021, doi: 10.1109/TIE.2020.3042112.

Information

- Research Area:Non-Destructive Testing

-

Investigators:

Ehsan Mohseni

, Gareth Pierce, Yashar Javadi, Charles Macleod, Anthony Gachagan, Nina Sweeney, Randika Vithanage - Publications:https://doi.org/10.1109/TIE.2020.3042112