In-process inspection of wire + arc additive manufactured components

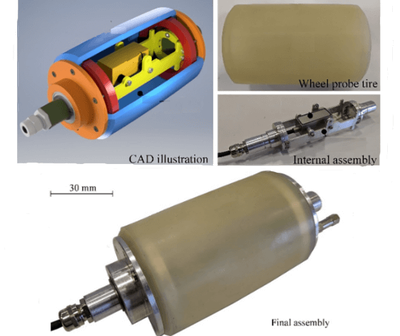

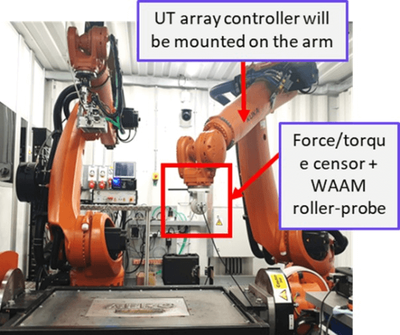

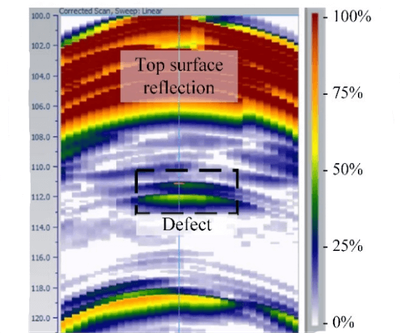

The wire + arc additive manufacturing (WAAM) process, which combines an electric arc as a heat source and metal wire as feedstock is proving to be very effective when producing medium to large scale metal components. The non-destructive testing (NDT) of WAAM parts, while they are being produced, provides early intervention opportunities to rectify manufacturing nonconformities and to perform in-process quality assurance of the parts. This attracts a significant amount of material, time and cost savings. Therefore, this paper presents the research, development and validation of a high temperature phased array ultrasound testing (PAUT) roller probe to perform robotically delivered in-process NDT of WAAM components. The experimental results confirm that the PAUT roller probe can endure surface temperatures up to 350 °C, can be autonomously deployed via a robotic arm and can detect 1 mm diameter flat-bottom holes located 6 mm, 9 mm and 12 mm deep under the unmachined surface of a Ti-6Al-4V WAAM calibration block.

Information

- Research Area:Non-Destructive Testing

-

Investigators:

Ehsan Mohseni

, Gareth Pierce, Charles Macleod, Anthony Gachagan, Randika Vithanage, Stewart Williams - Publications:https://doi.org/10.1016/j.jmapro.2022.06.045