Non-Destructive Evaluation of WAAM Components - Sensing and Transduction

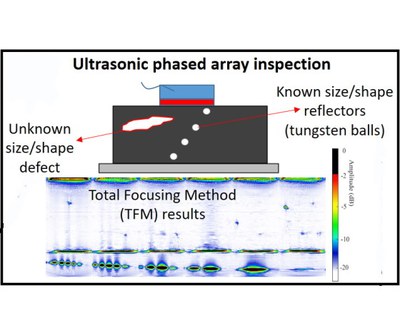

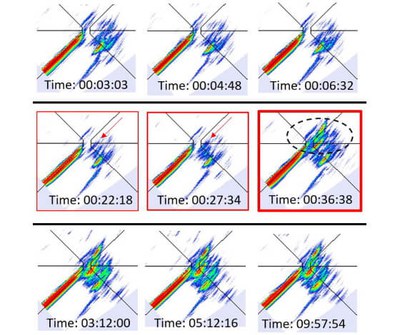

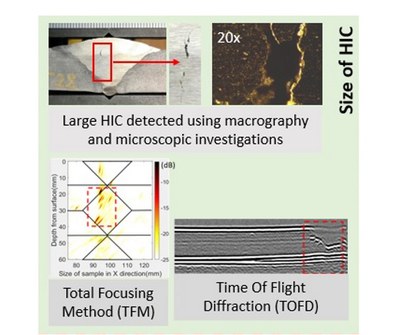

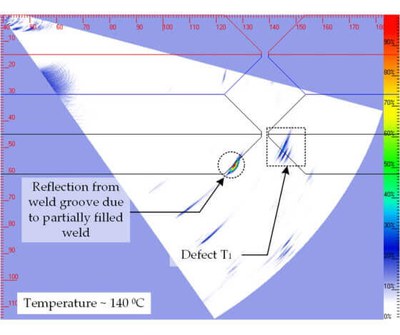

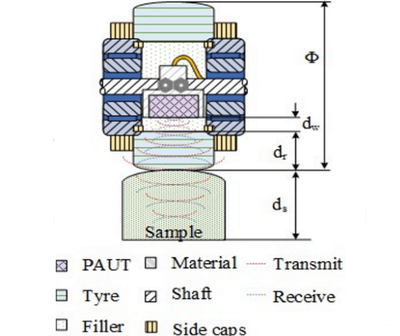

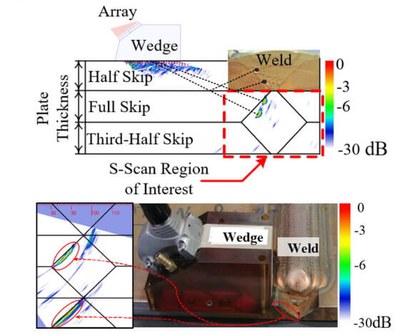

Contact Ultrasound Testing (UT) using arrays is among the few methods that can be effectively used within an automated WAAM inspection system, considering that the method provides bulk information and has a reasonable submillimeter detection sensitivity. The work package investigates development of a contact UT solution for automated in-process inspection of WAAM components. The task demands design for a High Temperature (HT) roller probe containing a UT array that can operate in harsh conditions at high temperatures. Acoustic, thermal and mechanical properties of the constituent components of the roller probe are studied to ensure that the probe can transfer enough wave energy into the test subject for acceptable UT signal-to-noise ratios, withstand HT of ~350˚C, and provide the mechanical resilience needed for the application. The roller probe is tailored for automation and it can accommodate for the curved and wavy WAAM layers, owing to its conformable soft silicon tire.

Information

- Research Area:Non-Destructive Testing

- Publication date:06 July 2020

Activities

List of all current activities related to the work package