Ultrasonic phased array inspection

Ultrasonic phased array inspection of a Wire + Arc Additive Manufactured (WAAM) sample with intentionally embedded defects

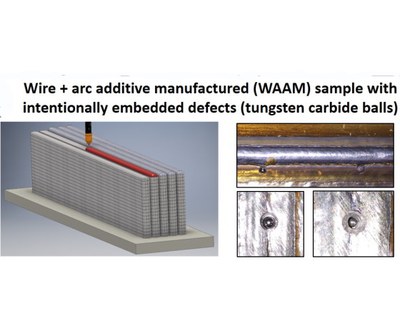

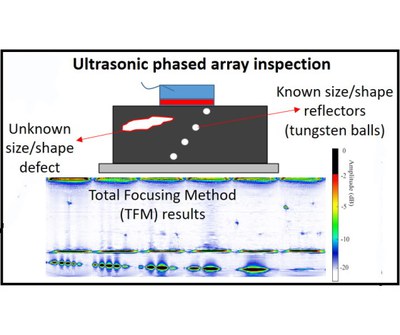

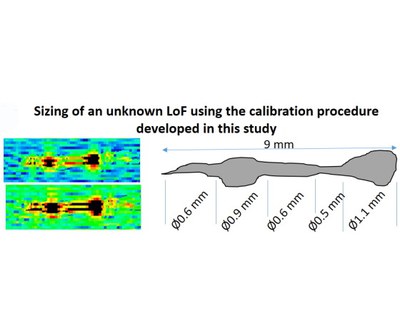

In this work, a Wire + Arc Additive Manufactured (WAAM) steel sample with intentionally embedded tungsten defects is studied. The artefacts are innovatively manufactured using tungsten carbide balls intentionally embedded inside the additive structure immediately after the deposition of 4th, 8th, 12th and 18th layers. This process provided several known size defects (ø1-3 mm tungsten carbide balls) to serve as ultrasonic reflectors, simulating defects within the WAAM sample. Using Phased Array Ultrasonic Testing (PAUT) and some advanced post-processing algorithms like Total Focusing Method (TFM), all the intentionally embedded tungsten defects were detected successfully. Owing to a lack of standards and codes for PAUT of WAAM components, a calibration method was introduced in this work using the novel manufacturing approach for the intentionally embedded tungsten defects combined with the advanced ultrasonic approaches of Full Matrix Capture (FMC) and TFM. All of this information was then used to estimate the size and shape of an unknown defect (a lack of fusion). This estimation was then validated by destructive analysis, showing a very good correlation with the PAUT results.

Y. Javadi et al., “Ultrasonic phased array inspection of a Wire + Arc Additive Manufactured (WAAM) sample with intentionally embedded defects,” Addit. Manuf., 2019, doi: 10.1016/j.addma.2019.100806.

Information

- Research Area:Non-Destructive Testing

- Publication date:01 October 2019

-

Investigators:

Ehsan Mohseni

, Gareth Pierce, Yashar Javadi, Charles Macleod, Anthony Gachagan, Momchil Vasilev, Stewart Williams - Publications:https://dx.doi.org/10.1016/j.addma.2019.100806