Stress and strain controlled fatigue behaviour

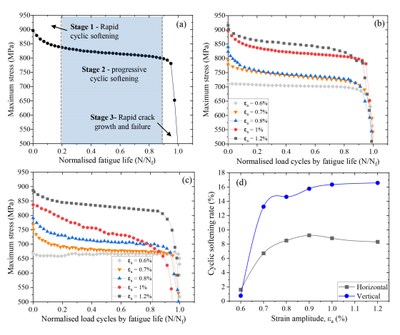

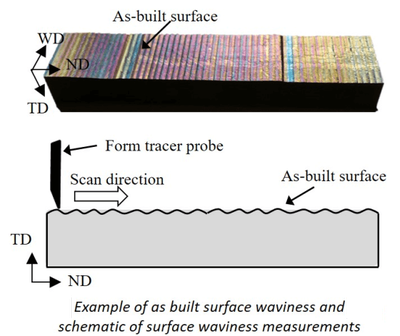

A major concern for structural application of metallic additive manufactured (AM) parts is their performance under cyclic loading. Unlike failures under static load, fatigue failures are caused by a local phenomenon, such as porosity, inclusion, and surface condition. This is particularly true in AM parts where fatigue strength is greatly influenced by surface texture and defects with respect to the theoretical properties for a given microstructure and AM process. Therefore, the integrity and durability of AM engineering parts requires thorough understanding of the fatigue damage process, failure mechanisms, and the influence of defects and microstructure. In conjunction with the material intrinsic fatigue properties via testing, fatigue life prediction models are being developed and validated by experimental tests. These models will enable our capabilities for design against fatigue and design for damage tolerance for metallic AM parts, leading to the qualification of AM parts.

Information

- Research Area:Material Performance

- Publication date:09 April 2020

Activities

List of all current activities related to the work package