Strain-controlled fatigue of Ti64

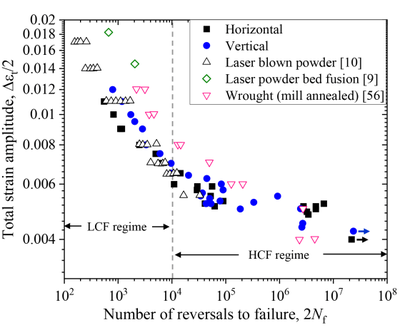

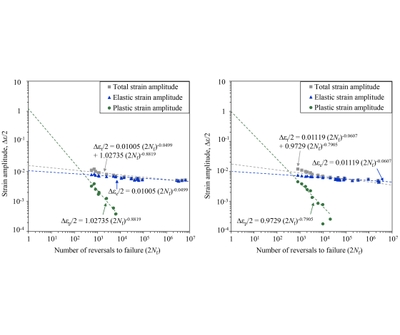

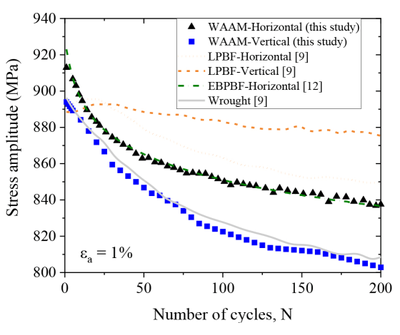

This paper presents the cyclic deformation behaviour and fatigue properties of a wire + arc additive manufactured Ti-6Al-4V alloy in the as built condition under strain-controlled test condition. Higher local energy input used to build the material has resulted in a coarser primary columnar β grain structure along with a coarser α microstructure compared to Ti-6Al-4V alloys produced by other additive manufacture processes. Test specimens were manufactured in horizontal and vertical orientations with respect to the deposited layers. Isotropic fatigue property was observed at lower applied strain values. When the strain amplitude was above 0.6%, the vertical samples, where the loading axis was parallel with the primary columnar β grains, showed marginally higher fatigue life owing to the material being more ductile in this direction. Moreover, higher cyclic softening rate by a factor of two was measured in the vertical samples. No porosity defects were found in the material. Cracks were initiated from either the α laths or α/β interface due to cyclic slip localisation.

K. Syed et al., “Strain controlled fatigue behaviour of a wire + arc additive manufactured Ti-6Al-4V,” Int J Fatigue, vol. 171, p. 107579, Jun. 2023, doi: 10.1016/J.IJFATIGUE.2023.107579.

Information

- Research Area:Material Performance

-

Investigators:

Abdul Khadar Syed

, Xiang Zhang, Stewart Williams - Publications:https://doi.org/10.1016/j.ijfatigue.2023.107579