Interrupted fatigue testing to monitor porosity defects

Interrupted fatigue testing with periodic tomography to monitor porosity defects in wire + arc additive manufactured Ti-6Al-4V

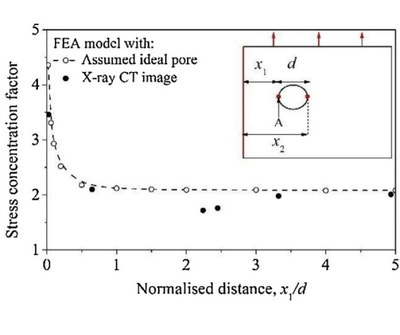

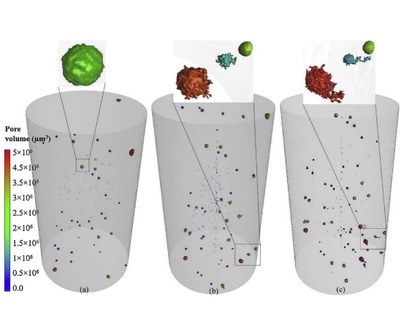

This study used specimens with purposely seeded pores by using contaminated wire at the specimen gauge section; pore size range 120-250 micrometres. Changes in the defect morphology under fatigue loads were monitored via periodic X-ray computed tomography (CT) scanning at several fatigue testing intervals. The near surface pores grew by approximately a factor of 2 and tortuous fatigue cracks were initiated and propagated towards the nearest free surface. Finite element analysis showed cyclic plastic deformation at the pore owing to the stress concentration effect; consequently, for an applied tension-tension cyclic stress (stress ratio 0.1), the local stress at the pore became a tension-compression nature (local stress ratio close to −1.0). Fatigue life was predicted using the notch fatigue approach and validated by experimental test.

R. Biswal et al., “Interrupted fatigue testing with periodic tomography to monitor porosity defects in wire + arc additive manufactured Ti-6Al-4V,” Addit. Manuf., 2019, doi: 10.1016/j.addma.2019.04.026

Information

- Research Area:Material Performance

- Publication date:01 August 2019

-

Investigators:

Abdul Khadar Syed

, Xiang Zhang, Romali Biswal - Publications:https://dx.doi.org/10.1016/j.addma.2019.04.026