Effect of isolated porosity defects on WAAM titanium alloy

Assessment of the effect of isolated porosity defects on the fatigue performance of additively manufactured titanium alloy

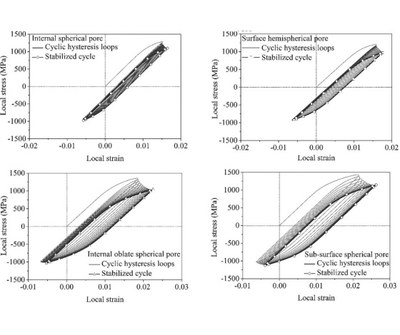

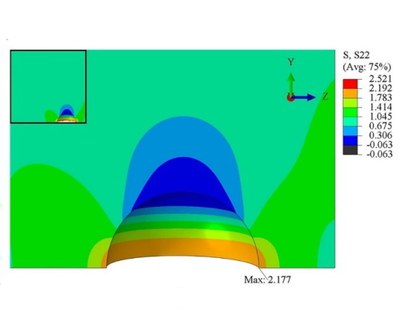

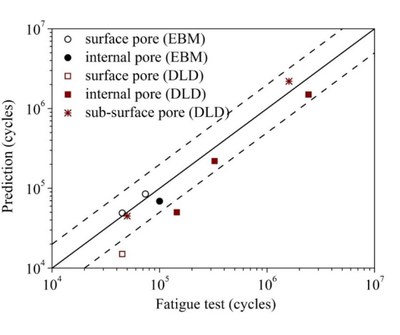

Studies on AM materials have shown fatigue strength reduction. This paper aimed at quantifying the influence of porosity defects, in terms of their shape, size, and location on the fatigue strength of AM Ti-6Al-4V. Ideal spherical and oblate spherical pores were modelled by finite element analysis. Results showed a stress concentration factor of 2.08 for internal spherical pore, 2.5 for oblate spherical pore, and 2.1 for surface hemispherical pore. Subsurface pores within a distance of the pore diameter from the free surface were found to be most critical. The material’s constitutive relation under the cyclic load was modelled by a mixed non-linear hardening rule that was calibrated with published literature on selective laser melted Ti-6Al-4V. The cyclic plasticity effect caused a local mean stress relaxation, which was found to be dependent on the pore geometry, the applied stress amplitude and the stress ratio. Fatigue life was predicted by using the calculated local strain amplitude and maximum stress in the Smith-Watson-Topper strain vs. life relationship. Predicted fatigue life was validated by literature test data. Parametric study showed that for internal pores, fatigue performance is more sensitive to the shape and location of the pore than the size. An S-N curve was proposed by the parametric study to account for the fatigue strength reduction due to internal gas pores.

R. Biswal, A. K. Syed, and X. Zhang, “Assessment of the effect of isolated porosity defects on the fatigue performance of additive manufactured titanium alloy,” Addit. Manuf., 2018, doi: 10.1016/j.addma.2018.08.024.

Information

- Research Area:Material Performance

- Publication date:01 October 2018

-

Investigators:

Abdul Khadar Syed

, Xiang Zhang, Romali Biswal - Publications:https://doi.org/10.1016/j.addma.2018.08.024