Criticality of porosity defects on WAAM titanium alloy

Criticality of porosity defects on the fatigue performance of wire + arc additive manufactured titanium alloy

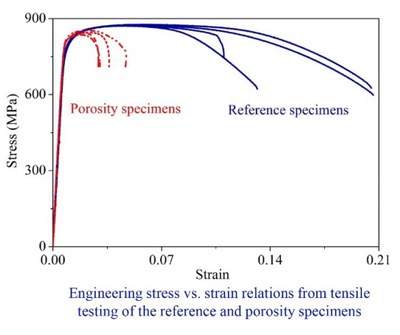

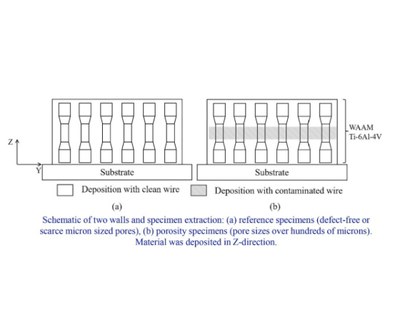

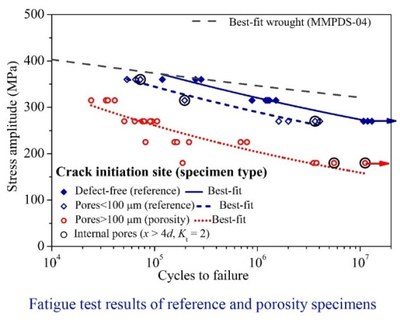

This study investigated the effect of porosity defects on the fatigue strength of WAAM Ti-6Al-4V. Unlike similar titanium alloys built by the powder bed fusion processes, WAAM Ti-6Al-4V seldom contains gas pores. However, feedstock may get contaminated that may cause pores of considerable size in the built materials. Two types of specimens were tested: (1) reference specimens built by nominal process; (2) specimens with intentional built porosity using contaminated wires to build the specimen gauge section. Test results have shown that static strength of the two groups was comparable, but the elongation in the porosity group was reduced by 60% and the fatigue strength was reduced by 33%. The stress intensity factor range of the crack initiating pore calculated by Murakami’s approach has provided good correlation with the fatigue life. The kink point on the data fitting curve corresponds well with the threshold value of the stress intensity factor range found in the literature.

R. Biswal et al., “Criticality of porosity defects on the fatigue performance of wire + arc additive manufactured titanium alloy,” Int. J. Fatigue, 2019, doi: 10.1016/j.ijfatigue.2019.01.017

Information

- Research Area:Material Performance

- Publication date:01 May 2019

-

Investigators:

Abdul Khadar Syed

, Xiang Zhang, Romali Biswal, Stewart Williams - Publications:https://doi.org/10.1016/j.ijfatigue.2019.01.017