Deposition strategies on tensile and fatigue properties

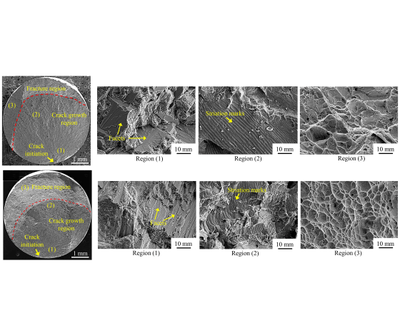

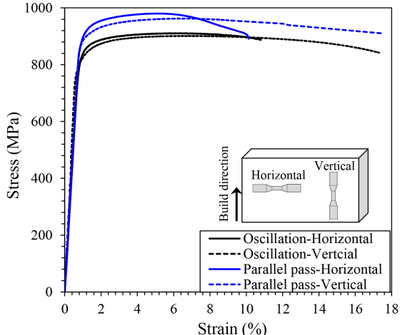

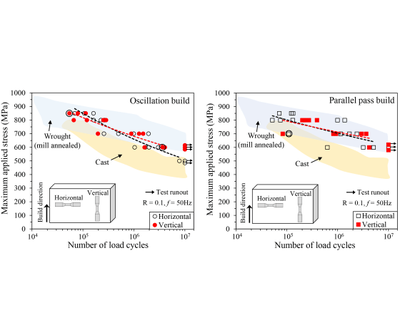

Influence of deposition strategies on the tensile and high cycle fatigue properties of a wire + arc additive manufactured Ti-6Al-4V was studied. Compared with the parallel pass build, the oscillation build had lower static strength due to its coarser transformation microstructure. However, the elongation values were similar. The presence of columnar primary β grains has resulted in anisotropic elongation values. The vertical samples with loading axis parallel to the primary β grains showed 40% higher elongation than the horizontal samples. Fatigue strength of both builds was comparable with their wrought counterpart and greater than casting. At 107 cycles, a fatigue strength of 600 MPa was achieved for the oscillation build vertical samples, and the parallel pass build in both orientations. Fractography analysis showed that 70% samples had crack initiation from pores of diameter ranging from 5 to 140 micrometres.

A. K. Syed, X. Zhang, A. Caballero, M. Shamir, and S. Williams, “Influence of deposition strategies on tensile and fatigue properties in a wire + arc additive manufactured Ti-6Al-4V,” Int. J. Fatigue, vol. 149, p. 106268, Aug. 2021, doi: 10.1016/j.ijfatigue.2021.106268.

Information

- Research Area:Material Performance

-

Investigators:

Armando Caballero

, Abdul Khadar Syed, Xiang Zhang, Stewart Williams - Publications:https://doi.org/10.1016/j.ijfatigue.2021.106268