Model-based calibration of ultrasound inspection of multi-pass welds

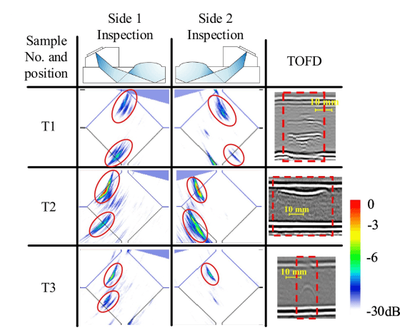

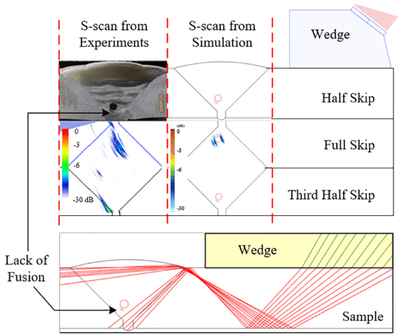

Automated In-Process Non-Destructive Testing (NDT) systems are rapidly gaining traction within the manufacturing industry as they have the potential to reduce manufacturing time and costs through removal of redundant wasted operations such as re-work. When considering calibration and verification of such systems, creating defects of known geometry and nature during the deposition of a weld can: (I) help examine the capability of the automated system to detect and characterise defects, (II) be used to form a database of signals associated with different defect types in order to train intelligent defect classification algorithms, and (III) act as a basis for in-process gain calibration during weld inspection at high temperatures, where the ultrasound beam can be skewed as a result of velocity gradients. In view of this, this paper investigates two unique methodologies for introducing: (a) lack of fusion weld defects by embedding tungsten in the weld and (b) creating artificial weld cracks by quenching to imitate the real cracking scenarios. According to the results of Phased Array Ultrasound Testing (PAUT) inspections the methodologies used for embedding the artificial defects in the weld were successful. The validity of inspections was also verified by extracting micrographs from the defective sections of the welds and model-based simulations, which suggested an accurate estimation of the signal amplitude recorded in PAUT.

E. Mohseni et al., “Model-assisted ultrasonic calibration using intentionally embedded defects for in-process weld inspection,” Mater Des, vol. 198, Jan. 2021, doi: 10.1016/j.matdes.2020.109330.

Information

- Research Area:Non-Destructive Testing

-

Investigators:

Ehsan Mohseni

, Gareth Pierce, Charles Macleod, Anthony Gachagan, Nina Sweeney, Randika Vithanage, Momchil Vasilev - Publications:https://doi.org/10.1016/j.matdes.2020.109330