Multi-layer ultrasonic imaging of WAAM components

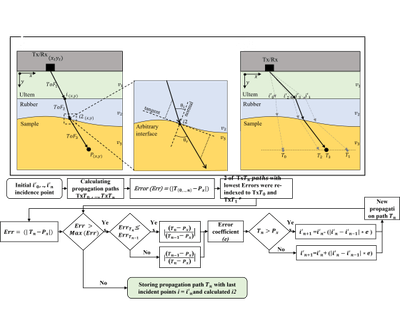

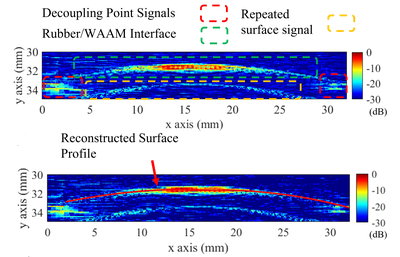

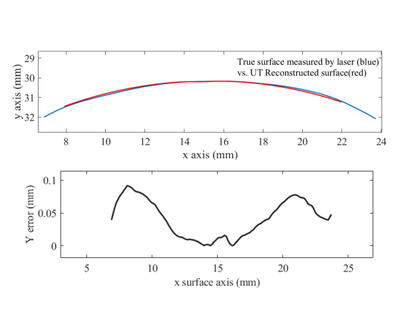

The detection of any potential flaws in metal additively manufactured (AM) components depends on non-destructive evaluation (NDE). The volumetric imaging capability in metallic components and the high defect sensitivity of ultrasound testing are well-known advantages. However, using traditional ultrasonic techniques on parts with curved and non-planar geometries, as those frequently found in AM builds, presents difficulties. In this body of work, the idea of inspecting Wire+Arc Additive Manufacture (WAAM) components from their non-planar as-built surface is introduced, doing away with the need for post-manufacturing machining. An autonomously deployed conformable phased array roller probe that uses Synthetic Aperture Focusing Technique (SAFT)-surface finding and multi-layer adaptive Total Focusing Method (TFM) algorithms to fully focussed imaging of the as-built WAAM component enables in-situ or post-manufacturing inspection. Through the as-built surface, two titanium WAAM components—one with reference bottom-drilled holes and the other with purposefully added Lack of Fusion (LoF) defects—are inspected to illustrate the imaging approach's basic principles. The approach's suitability for volumetric or layer-specific inspection of as-built WAAM components is confirmed by the TFM images of the WAAM components, which have a suitable Signal-to-Noise Ratio to enable defect detection and strong agreement against reference X-Ray CT data.

R. Zimermann et al., “Multi-layer ultrasonic imaging of as-built Wire + Arc Additive Manufactured components,” Addit Manuf, vol. 48, p. 102398, Dec. 2021, doi: 10.1016/j.addma.2021.102398.

Information

- Research Area:Non-Destructive Testing

-

Investigators:

Ehsan Mohseni

, Gareth Pierce, Yashar Javadi, Charles Macleod, Anthony Gachagan, Randika Vithanage, Stewart Williams - Publications:https://doi.org/10.1016/j.addma.2021.102398