In-Process NDE using dry-coupled ultrasound and eddy-currents

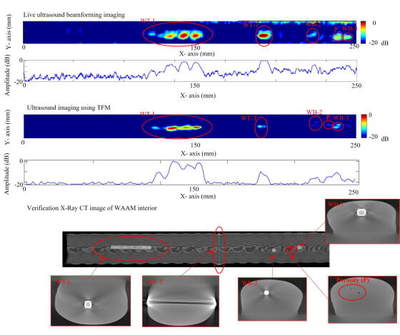

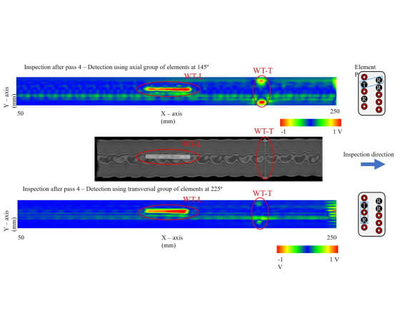

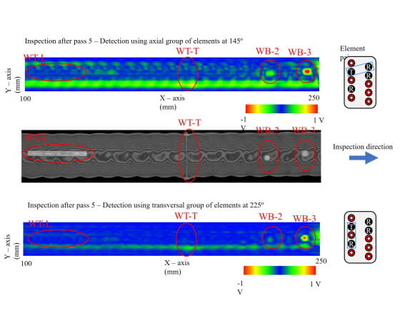

Metal additive manufacturing is rapidly gaining popularity and interest from sectors aiming to produce larger-scale high-value components cost-effectively. To ensure each component is leaving the fabrication cell defect-free, it is highly desirable to inspect each layer or selected volume of the build. This is a significant challenge, given that conventional non-destructive evaluation (NDE) is a post-manufacturing operation. The opportunity exists in the development of novel flexible automated manufacturing systems aiming to merge deposition and inspection. Hence, enabling defect detection at the point of the creation allows subsequent rapid repair or reduction in scrappage. In this work, the authors present research from one such multi-robot cell, where a directed energy deposition process called wire + arc additive manufacture is used to build components while novel in-process ultrasound and eddy-current approaches are deployed to inspect a component with artificially embedded reflectors. The outcome of this work demonstrates a promising ability to merge manufacturing and NDE into a single process and hence, strengthen the overall benefits of metal additive manufacturing fields.

Zimermann, R., Mohseni, E., Foster, E. A., Vasilev, M., Loukas, C., Vithanage, R. K. W., Macleod, C. N., Lines, D., Silva, M. P. E. E., Fitzpatrick, S., Halavage, S., McKegney, S., Rizwan, M. K., Pierce, S. G., Williams, S., & Ding, J. (2023). In-process non-destructive evaluation of metal additive manufactured components at build using ultrasound and eddy-current approaches. Journal of Manufacturing Processes, 107, 549–558. https://doi.org/10.1016/j.jmapro.2023.10.063

Information

- Research Area:Non-Destructive Testing

-

Investigators:

Ehsan Mohseni

, Gareth Pierce, Charles Macleod, Randika Vithanage, Momchil Vasilev, Stewart Williams, Muhammad Khalid Rizwan - Publications:https://doi.org/10.1016/j.jmapro.2023.10.063