In-process inspection of multi-pass welding

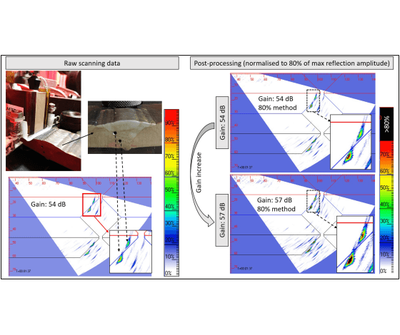

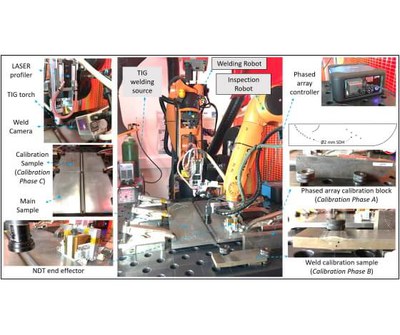

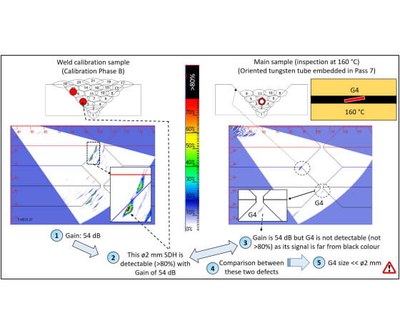

In multi-pass welding, there is increasing motivation to move towards in-process defect detection to enable real-time repair; thus avoiding deposition of more layers over a defective weld pass. All defect detection techniques require a consistent and repeatable approach to calibration to ensure that measured defect sizing is accurate. Conventional approaches to calibration employ fixed test blocks with known defect sizes, however, this methodology can lead to incorrect sizing when considering complex geometries, materials with challenging microstructure, and the significant thermal gradients present in materials during the inter-pass inspection period. To circumvent these challenges, the authors present a novel approach to calibration and introduce the concept of in-process calibration applied to ultrasonic Non-Destructive Testing (NDT). The new concept is centred around the manufacturing of a second duplication sample, containing intentionally-embedded tungsten inclusions, with identical process parameters as the main sample. Both samples are then inspected using a high-temperature robotic NDT process to allow direct comparative measurements to be established between the real part and the calibration sample. It is demonstrated that in-process weld defect detection using the in-process calibration technique can more reliably identify defects in samples which would otherwise pass the acceptance test using a traditional calibration.

Y. Javadi et al., “In-process calibration of a non-destructive testing system used for in-process inspection of multi-pass welding,” Mater Des, vol. 195, p. 108981, Oct. 2020, doi: 10.1016/j.matdes.2020.108981.

Information

- Research Area:Non-Destructive Testing

-

Investigators:

Ehsan Mohseni

, Gareth Pierce, Yashar Javadi, Charles Macleod, Anthony Gachagan, Nina Sweeney, Randika Vithanage, Momchil Vasilev, Theodosia Stratoudaki - Publications:https://doi.org/10.1016/j.matdes.2020.108981