Deposition strategies on fatigue crack growth

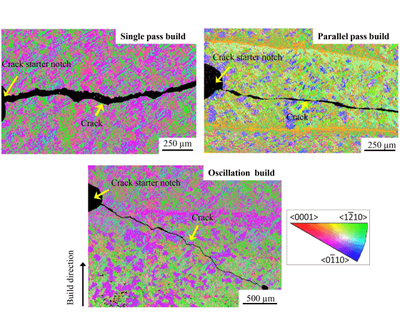

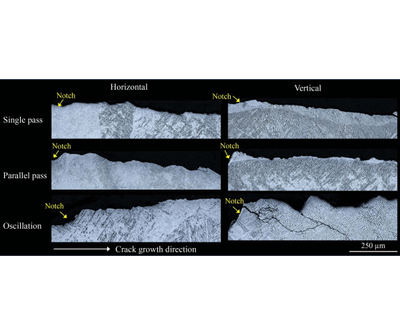

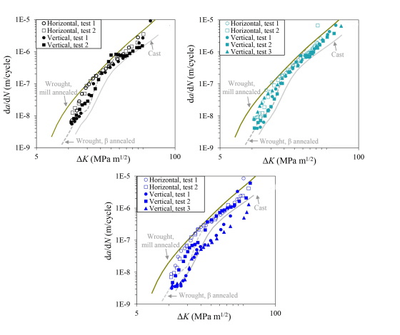

The influence of three deposition strategies on the fatigue crack growth behaviour of Wire + Arc Additive Manufactured (WAAM) Ti-6Al-4V has been investigated in the as-built condition. Test samples were prepared using single pass, parallel pass, and oscillation deposition strategies and tested with cracks propagating parallel and normal to the plane of deposition. Due to the higher local heat input, the oscillation build exhibited a significantly coarser columnar β grain structure as well as a coarser transformation microstructure, compared to the single pass and parallel pass builds, which were very similar. Among the three build methods, the lowest crack growth rates were found with the oscillation build. The crack growth data was found to broadly fall between that of a recrystallized α (mill-annealed) and β annealed wrought material, with the oscillation strategy build behaving more similarly to a β annealed microstructure. The fatigue crack growth rate was lower when cracks were propagated perpendicular to the build layers. For each build strategy, a greater microstructural influence on crack growth rate was found at lower levels of stress intensity factor range(< 25 MPa.m1/2). However, the anisotropy and scatter in the data was much more significant in the case of the oscillation build. These differences have been attributed to the stronger α microtexture heterogeneity present in the oscillation build, which led to a greater crack deflection and bifurcation, giving rise to lower crack growth rates and a higher sensitivity to the anisotropy caused by the directional β grain structure.

A. K. Syed et al., “Effect of deposition strategies on fatigue crack growth behaviour of wire + arc additive manufactured titanium alloy Ti–6Al–4V,” Mater. Sci. Eng. A, vol. 814, 2021, doi: 10.1016/j.msea.2021.141194.

Information

- Research Area:Material Performance

-

Investigators:

Abdul Khadar Syed

, Phil Prangnell, Xiang Zhang, Alec Davis, Stewart Williams - Publications:https://doi.org/10.1016/j.msea.2021.141194