WAAM Ti-6Al-4V by Zrn & TiN Inoculation

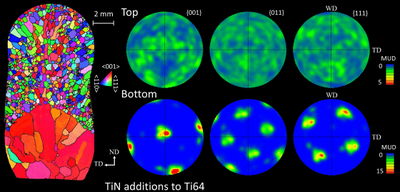

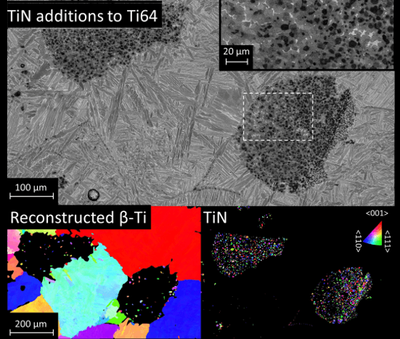

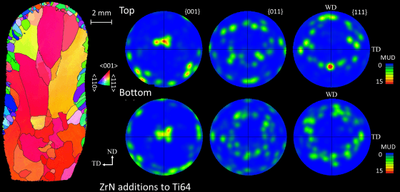

Industrial sectors such as aerospace can benefit from the potential cost and lead-time reductions of manufacturing large near-net-shape titanium components by wire-arc additive manufacturing(WAAM). However, deposition of titanium alloys, such asTi-6Al-4V (Ti64), with standard WAAM processing parameters, can produce coarse and columnarβ-grain structures that exhibit strong<001> fibre textures that are detrimental to mechanical properties. In this work, two cubic nitride phases, TiN and ZrN, were investigated as grain refiners to break up the columnarβ-grain structure and weaken the strong textures in WAAM Ti64. Experimental trials were performed by attaching powder to the deposited WAAM track surfaces to avoid manufacturing new wire and reduce costs. The columnarβ-grain structure was successfully refined with the TiN particle additions, with a 300μm average grain size, but the ZrN particles were ineffective at the concentration investigated. Theβ-titanium grains were found to have nucleated from TiN particle clusters, and through the Burgers orientation relationship and the electron backscatter diffraction technique, a Kurdjumov-Sachsorientation relationship was identified between the TiN particles and theβ-titanium grain nuclei.

Kennedy, J. R., Davis, A. E., Caballero, A. E., Williams, S., Pickering, E. J., & Prangnell, P. B. (2021). The potential for grain refinement of Wire-Arc Additive Manufactured (WAAM) Ti-6Al-4V by ZrN and TiN inoculation. Additive Manufacturing, 40. https://doi.org/10.1016/j.addma.2021.101928

Information

- Research Area:Material Development

- Publication date:01 April 2021

-

Investigators:

Armando Caballero

, Phil Prangnell, Alec Davis, Stewart Williams - Publications:https://doi.org/10.1016/j.addma.2021.101928