β-grain structures in Ti-6Al-4V

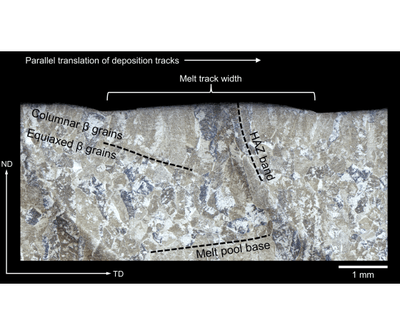

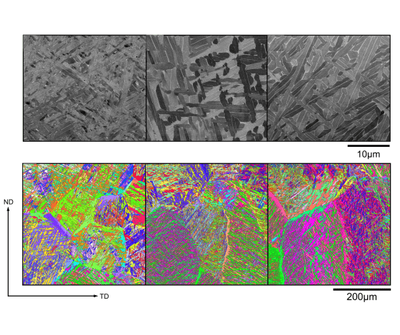

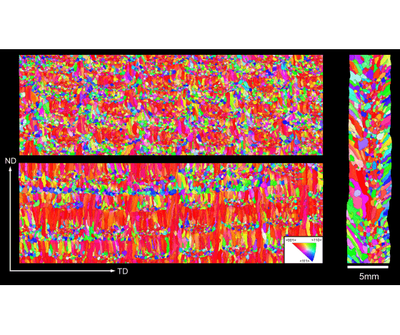

Coarse, columnar, β-grain structures are typically found in Ti-6Al-4V (Ti64) components produced using high-deposition-rate, directed-energy-deposition additive manufacturing (DED-AM) processes, which lead to mechanical anisotropy. Fine, heterogeneous lamellar transformations microstructures are also found, which are dissimilar to those found in common wrought products. This is a consequence of the insufficient constitutional supercooling at the solidification front, and the intrinsic rapid thermal cycling and high cooling rates of the material in DED-AM processes. In this work, we characterised in detail, for the first time, the more refined β-grain structures present in components built by the novel coaxial electron beam wire DED-AM(CEWAM) process, and further investigated the potential to directly replicate typical, damage tolerant, β-annealed Ti64 aerospace forgings. Electron backscatter diffraction analysis andβ-grain reconstruction of three orthogonal cross sections showed that, due to the lower energy density solidification conditions, the CEWAM process has dissimilar melt conditions to other DED-AM processes that produces the refinedβ-grain structure. However, mixed grain structures were found in larger multi-track components. β-annealing of the CEWAM samples, with a slow subsequent cooling rate, homogenised theβ-grain structure and led to colonyαnucleation, which demonstrated the possibility of direct wrought component substitution. This was only possible due to the as-deposited, refined, β-grain structure, which also led to weaker textures than that found in typical wrought components.

Davis, A. E., Kennedy, J. R., Strong, D., Kovalchuk, D., Porter, S., & Prangnell, P. B. (2021). Tailoring equiaxed β-grain structures in Ti-6Al-4V coaxial electron beam wire additive manufacturing. Materialia, 20. https://doi.org/10.1016/j.mtla.2021.101202

Information

- Research Area:Material Development

-

Investigators:

Phil Prangnell

, Alec Davis - Publications:https://doi.org/10.1016/j.mtla.2021.101202