Efficient Process Modelling for Wire Based Direct Energy Deposition Process

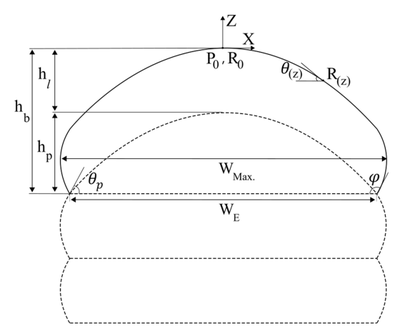

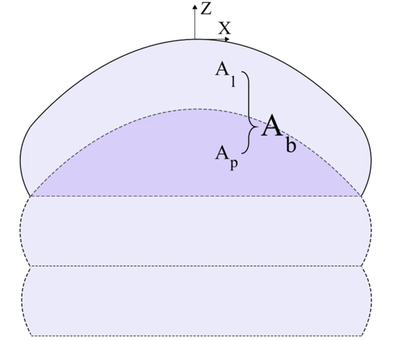

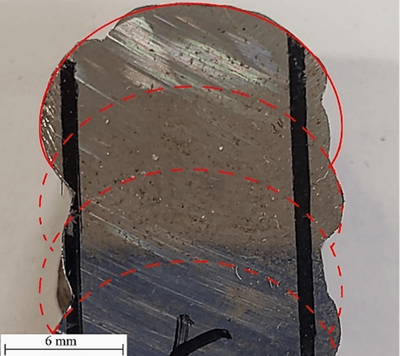

Wire-based directed energy deposition (w-DED) is an additive manufacturing process well-suited for building large-scale structural components. Deposit bead geometry and its relation to process parameters is a vital aspect of a w-DED process, which is crucial for preventing defects and minimising material waste. In this study, a thermo-capillary-gravity bidirectional analytical model is developed based on the fundamental governing physics, enabling fast predictions of both w-DED bead geometries and process parameters. A novel method is also proposed to determine the power transfer efficiency and wire melting efficiency defined in the model. In the forward modelling, deposit bead geometries, such as layer height and width, can be predicted for given process parameters and material properties. In the reverse modelling, the outputs of the model are process parameters, including heat source power and travel speed, to achieve the deposit bead geometries as required for a given application. This bidirectional modelling approach is applicable to different w-DED processes, and it has been validated for the deposition of steel walls using plasma transferred arc and cold wire gas metal arc processes. The developed bidirectional analytical model could be used as an efficient and reliable tool for w-DED process evaluation and design.

A. M. Haghighi, J. Ding, Y. Sun, C. Wang, and S. Williams, “Thermo-capillary-gravity bidirectional modelling for evaluation and design of wire-based directed energy deposition additive manufacturing,” J Manuf Process, vol. 107, pp. 320–332, Dec. 2023, doi: 10.1016/j.jmapro.2023.09.069.

Information

- Research Area:Process Modelling

-

Investigators:

Alireza M. Haghighi

, Chong Wang, Stewart Williams, Yongle Sun - Publications:https://doi.org/10.1016/j.jmapro.2023.09.069