Aluminium Zinc Alloy Development

Wire Laser Arc Additive Manufacture of Aluminium Zinc Alloys

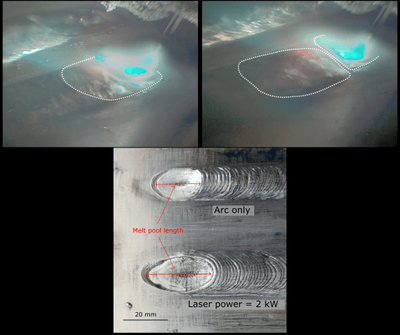

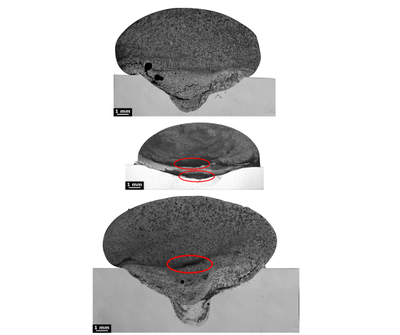

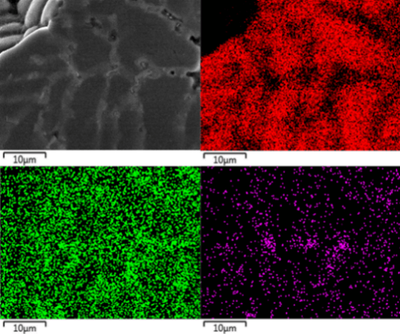

Aluminium zinc alloys are widely used in the aerospace industry due to their high strength. However, only a few studies have been reported on the additive manufacture of aluminium zinc alloys. This rarity is due to the difficulties occurring during the fusion processing of these alloys and to the lack of available raw material. This paper presents an alternative process used for the deposition of aluminium zinc alloys. In this study, a Wire Laser Arc Additive Manufacture (WLAAM) system was used. This consisted of a gas metal arc power source, used to generate the melt pool, and a laser beam applied to control the melt pool size. By using this approach, it was possible to produce an elongated melt pool and feed zinc into it with a cold wire without compromising the process stability. A welding camera along with a system measuring the arc voltage and current was used to monitor the process. Different process parameters and configurations were investigated along with their effect on process stability and deposited material microstructure. A very high zinc concentration was achieved in the deposited material without macro-segregation.

Eimer, W. Suder, S. Williams, and J. Ding, “Wire Laser Arc Additive Manufacture of aluminium zinc alloys,” Weld. World, 2020, doi: 10.1007/s40194-020-00872-9.

Information

- Research Area:Material Development

- Publication date:11 March 2020

-

Investigators:

Eloise Eimer

, Wojciech Suder, Stewart Williams - Publications:https://link.springer.com/article/10.1007/s40194-020-00872-9