High-strenght aluminium WAAM alloys

Aluminium copper magnesium alloys are widely used in the aerospace sector. Wire-based Directed Energy Deposition could replace conventional manufacturing routes to build large and semi-complex components for this industry if high mechanical performance can be achieved in the deposit.

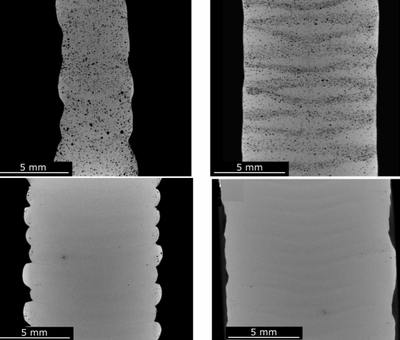

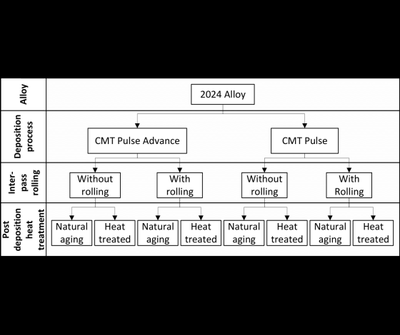

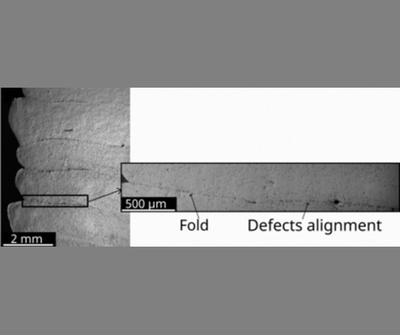

The scope of this study was to assess the effect of inter-pass rolling on a 2024 aluminium alloy wire-based DED built structure and to investigate the impact of cold work during the deposition process on the microstructure and mechanical performances. The 2024 aluminium alloy was deposited using two variants of gas metal arc process, and the effects of the deposition process, cold work and heat treatment were studied using macro and microstructural observations, hardness measurement and tensile tests. The material response to inter-pass rolling and the formation of rolling defects was found to depend on the deposition process variant and bead geometry. While a significant strengthening of the deposit was observed with one process, only a drastic reduction of defects was observed with the second. It was also found that the application of cold work and heat treatment led to lowering of anisotropy and higher ductility when compared with heat-treated deposit without any inter-pass rolling.

E. Eimer et al., “Effect of inter layer cold work on 2024 aluminium alloy produced by wire directed energy deposition,” Materials Science and Engineering: A, vol. 880, p. 145272, Jul. 2023, doi: 10.1016/j.msea.2023.145272.

Information

- Research Area:Material Development

-

Investigators:

Eloise Eimer

, Stewart Williams - Publications:https://doi.org/10.1016/j.msea.2023.145272