Hybrid manufacture of aluminium components

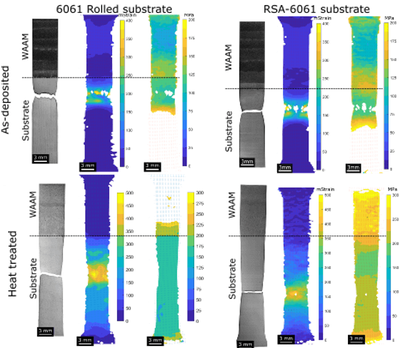

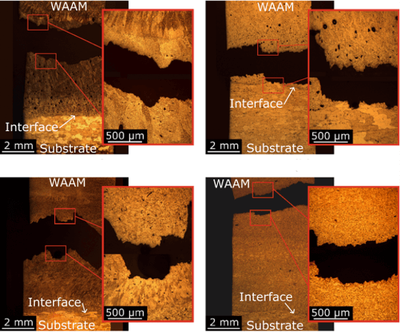

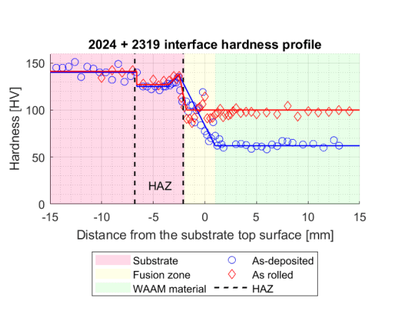

Wire and Arc Additive manufacturing (WAAM) is a Direct Energy Deposition process suitable for the manufacture of large aluminium components. Additive Manufacturing can enable the production of functionally graded structure which could be done by integrating the substrate required to start the deposition into the final component. This paper aims to assess the possibility of including a substrate in a component by investigating the mechanical performances of the interface between a wrought plate and WAAM deposit. Four substrates alloys and 2319 WAAM alloy were investigated. Inter-layer rolling and heat treatment, process steps known for improving the properties of WAAM deposit, were implemented. Each interface was examined using microhardness profiles, tensile tests, post rupture fractography and microstructural analysis. The WAAM deposit hardness was lower than that of the substrate in the as-deposited condition. Although the interface had no impact when using the same alloy for both substrate and wire, the weakest point of the combination was at the interface in dissimilar alloy combination. Heat treatment reduced the properties difference between the substrate and WAAM deposit. Inter-pass rolling strengthen the WAAM deposit without impacting the substrate and eliminated the micro crack that occasionally formed in the fusion zone in the as-deposited condition.

E. Eimer, S. Williams, J. Ding, S. Ganguly, and B. Chehab, “Mechanical performances of the interface between the substrate and deposited material in aluminium wire Direct Energy Deposition,” Mater Des, vol. 225, p. 111594, Jan. 2023,

doi: 10.1016/J.MATDES.2023.111594.

Information

- Research Area:Material Development

-

Investigators:

Eloise Eimer

, Stewart Williams - Publications:https://doi.org/10.1016/j.matdes.2023.111594