Automated mapping

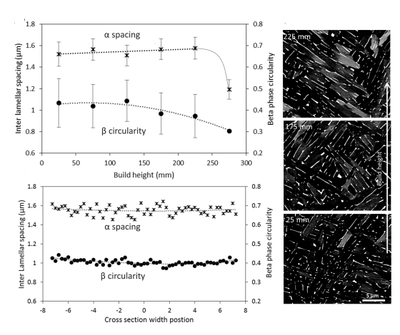

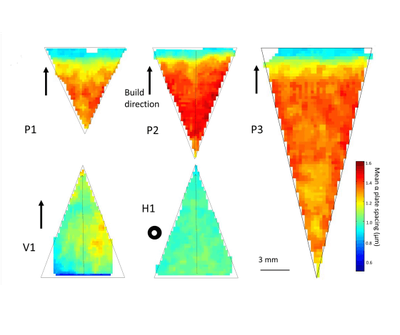

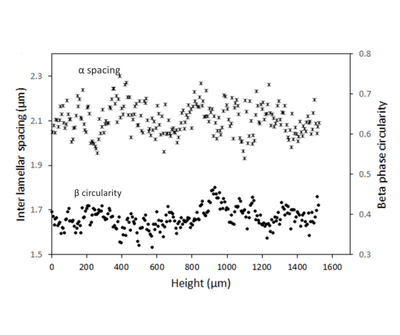

In powder bed and direct energy deposition additive manufacturing (AM), due to the intrinsic cyclical passes of the heat source, each deposited layer is re-heated multiple times and thus experiences a complex thermal history. With titanium alloys, like Ti-6Al-4V, this produces drastic local variation in the α + β transformation microstructure that produces significant mechanical anisotropy. To better quantify this variability in the microstructure throughout an AM-built part, an automated analysis tool was developed to map the α-phase inter-lamellar spacing and spheroidicity of the β phase, and was tested against manually obtained data. This method utilised automated batch image analysis of many images taken in a high-resolution SEM using a mapping function. The errors due to drift in the SEM operating parameters (e.g. working distance, backscatter detector contrast) were small (< 3%). Two example case studies – electron beam melting (EBM) and wire-arc additive manufacturing (WAAM) – representing different ends of the AM spectrum were presented and discussed. The EBM sample exhibited microstructure change over the build height and geometry but varied little over the short-range, whereas the WAAM component suffered from short-range microstructure variation associated with the heat affected zone bands.

Zhao, A. Ho, A. Davis, A. Antonysamy, and P. Prangnell, “Automated image mapping and quantification of microstructure heterogeneity in additive manufactured Ti6Al4V,” Mater. Charact., 2019, doi: 10.1016/j.matchar.2018.10.027

Information

- Research Area:Material Development

- Publication date:01 January 2019

-

Investigators:

Phil Prangnell

, Alec Davis - Publications:https://doi.org/10.1016/j.matchar.2018.10.027