Refinement in High Deposition Rate Wire-Arc AM Ti-6Al-4V

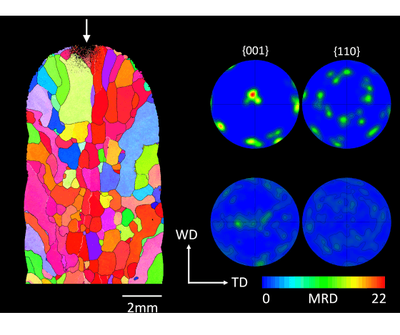

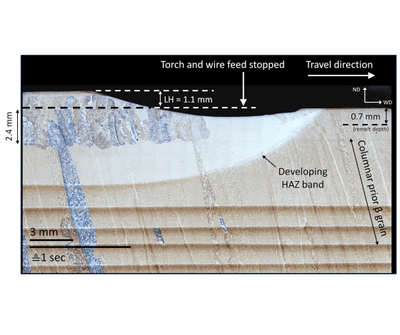

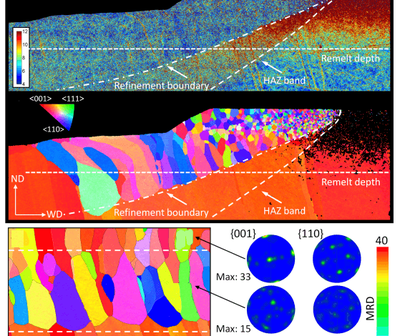

Surface deformation, applied in-process by machine hammer peening (MHP), has the potential to refine the coarse columnar β-grain structures normally found in high deposition rate Wire-Arc Additive Manufacturing (WAAM) processes with Ti alloys like Ti-6Al-4V. Effective refinement, as well as a reduction in texture strength, has been achieved in relatively thick sections and to a depth that is greater than that expected from the surface deformation induced by MHP. By application of MHP to each deposition track, the average β-grain size could be reduced from cm’s to less than 0.5 mm. Systematic experiments have been performed to investigate the origin of this interesting effect, which included ‘stop-action’ trials and separation of the strain and temperature gradients induced by the two process steps. The maximum depth of the plastic deformation from MHP required to generate new β-grain orientations was determined by electron backscatter diffraction local average misorientation analysis to be < 0.5 mm, which was less than the melt pool depth in the WAAM process. Nevertheless, new β-grain orientations were observed to form within the peened layer ahead of the approaching heat source as the peak temperature rose above the β transus, which then grew into the less deformed core of the wall as the temperature rose. This allowed the new grain orientations to penetrate deeper than the melt pool depth and survive to act as substrates for epitaxial growth at the fusion boundary during solidification, resulting in significant grain refinement.

J. R. Hönnige et al., “The Effectiveness of Grain Refinement by Machine Hammer Peening in High Deposition Rate Wire-Arc AM Ti-6Al-4V,” Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2020, doi: 10.1007/s11661-020-05781-6.

Information

- Research Area:Material Development

-

Investigators:

Phil Prangnell

, Alec Davis, Stewart Williams - Publications:https://doi.org/10.1007/s11661-020-05781-6