Strain mapping in Ti64

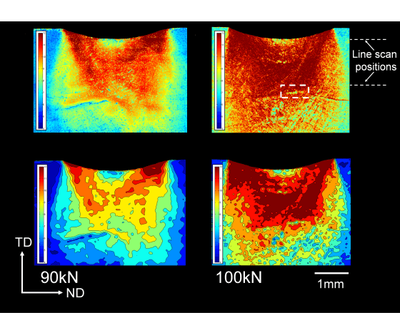

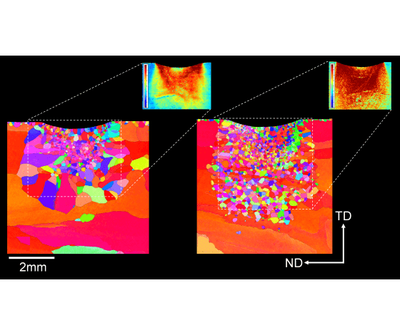

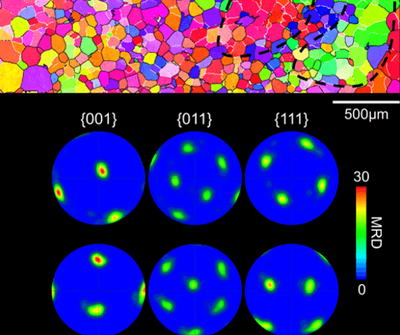

Inter-pass deformation is an effective method for refining the coarse β-grain structure normally produced in high-deposition-rate additive manufacturing processes, like wire-arc additive manufacturing. The effectiveness of applying contoured surface rolling deformation tracks to each added layer has been studied by developing, and applying, a large-area SEM-based strain mapping technique. This technique is based on calibration of the average point-to-point Local Average Misorientation (LAM) of α-phase lamellar variants in EBSD orientation data to the local effective plastic strain. Although limited in the strain range that can be measured, the technique has proven to be very effective for identifying the size and depth of the plastic zone induced by surface rolling, as well as the local strain distribution, up to a saturation limit of ~12%. The strain fields mapped showed a close correlation to the region and level of recrystallization that occurred in the deformation zones during rapid re-heating through the β transus. The β recrystallization identified was consistent with the local strain distribution within the plastic zones measured by the LAM method and previous work on the recrystallization mechanisms operating in WAAM inter-pass deformation processes.

E. Davis, J. R. Hönnige, F. Martina, and P. B. Prangnell, “Quantification of strain fields and grain refinement in Ti-6Al-4V inter-pass rolled wire-arc AM by EBSD misorientation analysis,” Mater. Charact., 2020, doi: 10.1016/j.matchar.2020.110673.

Information

- Research Area:Material Development

- Publication date:01 October 2020

-

Investigators:

Phil Prangnell

, Alec Davis - Publications:https://doi.org/10.1016/j.matchar.2020.110673