Beta Recrystallization

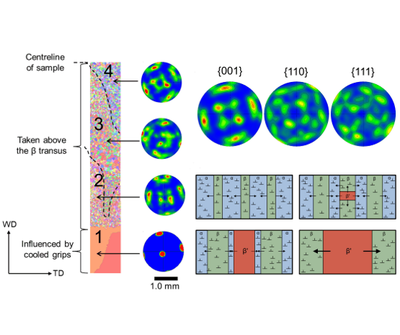

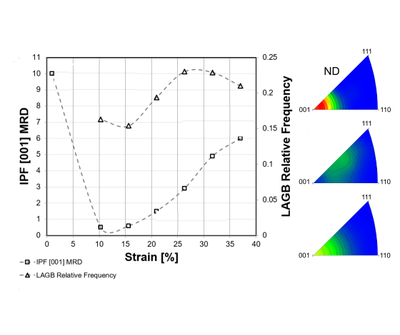

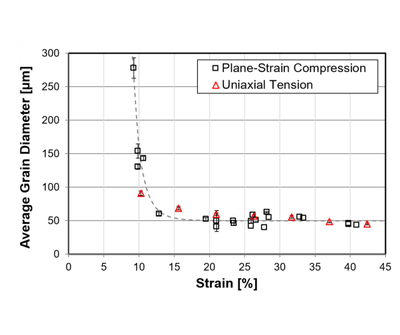

The coarse columnar 𝛽 grains in Ti-6Al-4V WAAM can be refined by relatively low strain inter-pass deformation Simulation, with rapid heating, has shown this may partly occur by a novel recrystallization mechanism that involves twinning during 𝛽 regrowth through the 𝛼- 𝛽 transus, as a result of the prior deformation promoting faults in the 𝛼- 𝛽 interface, which produces a unique micro-texture in each parent 𝛽 grain. Here, this potentia mechanism has been investigated further, using a different deformation mode – uniaxial tensile deformation rather than plane strain compression – to enable the texture contribution from conventional recrystallization to be more unambiguously discriminated. The tensile-deformed samples are shown to produce the same unusual unique micro-texture seen previously, at low strains, despite the different deformation mode, but this disappeared at higher strains, which provides more evidence in support of this new rapid heating 𝛽 recrystallization mechanism.

A. E. Davis, A. Caballero, and P. B. Prangnell, “Confirmation of rapid-heating β recrystallization in wire-arc additively manufactured Ti-6Al-4V,” Materialia, vol. 13, 2020, doi: 10.1016/j.mtla.2020.100857

Information

- Research Area:Material Development

- Publication date:02 September 2020

-

Investigators:

Armando Caballero

, Phil Prangnell, Alec Davis - Publications:https://doi.org/10.1016/j.mtla.2020.100857