Multi-energy source (MES) system

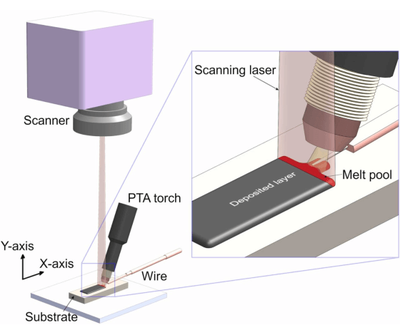

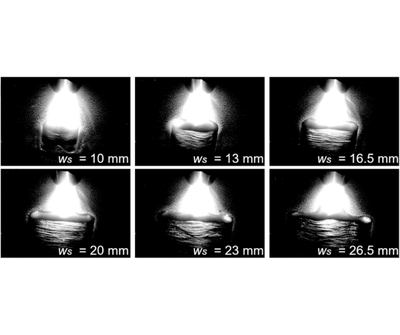

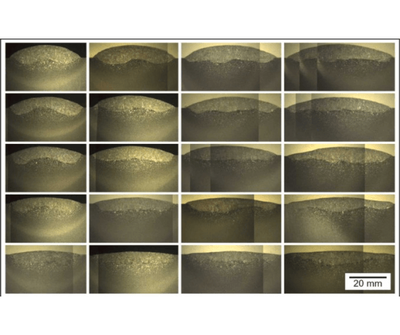

A multi-energy source (MES) method featuring a high-power scanning laser (SL) was used to achieve independent control of layer width and height in a wire-based directed energy deposit (w-DED) process. In the MES system, a plasma transferred arc (PTA) was employed to create an initial melt pool and melt the wire, and a SL was used to reshape the melt pool and precisely control the bead width. The distance between the SL and the PTA and different laser scanning strategies were investigated. Images of the melt pool with varying scanning widths were captured. A bead shape control strategy was demonstrated by using the wire feed speed to control layer height and the laser scanning width to control the layer width independent of each other. The advancing speed was adjusted in proportion to the scanning width to keep the same specific process energy of the SL. The experimental results demonstrated that the MES approach provides independent control of layer width and height. Some single-pass walls were built using the MES to show that MES can be used for w-DED additive manufacturing.

Chen, S. Williams, J. Ding, C. Wang, and W. Suder, “Multi-energy source (MES) configuration for bead shape control in wire-based directed energy deposition (w-DED),” J Mater Process Technol, vol. 304, p. 117549, Jun. 2022, doi: 10.1016/j.jmatprotec.2022.117549.

Information

- Research Area:Process Development

-

Investigators:

Chong Wang

, Guangyu Chen, Wojciech Suder, Stewart Williams - Publications:https://doi.org/10.1016/j.jmatprotec.2022.117549